A spring is defined as an elastic body, whose function is to distort when loaded and to recover its original shape when the load is removed. It absorbs or controls energy due to either shock or vibration so it can be used as shock absorbers and vibration dampers. It is also used to apply forces, as in brakes, clutches, and spring-loaded valves. We have already discussed different types of Springs in the previous article. We also discussed the Compression Springs Nomenclature. Let us now discuss the Buckling of Compression Springs.

What is buckling?

In Engineering, Buckling is failure mode characterized by a sudden failure of a structural member subjected to high compressive stresses, where the actual compressive stresses at failure are smaller than the ultimate compressive stresses that the material is capable of withstanding. This mode of failure is also described as failure due to elastic instability. Mathematical analysis of buckling makes use of an axial load eccentricity that introduces a moment, which does not form part of the primary forces to which the member is subjected.

Buckling of Compression Springs

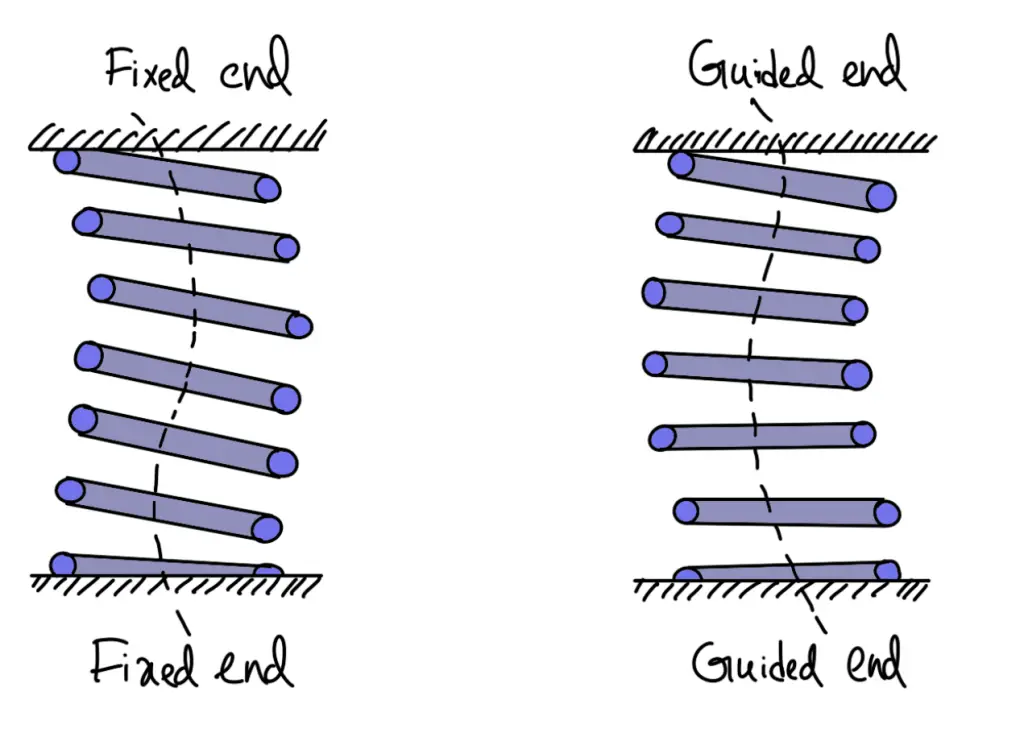

It has been found experimentally that when the free length of the spring (LF) is more than four times the mean or pitch diameter (D), then the spring behaves like a column and may fail by buckling at a comparatively low load as shown in the following figure.

The critical axial load (Wcr) that causes buckling may be calculated by using the following relation, i.e.

Wcr = k × KB × LF

Where

k = Spring rate or stiffness of the spring = W/δ,

LF = Free length of the spring, and

KB = Buckling factor depending upon the ratio LF / D

The buckling factor (KB) for the hinged end and built-in end springs may be taken from the following table.

| LF/D | Hinged end spring | Built-in end spring |

| 1 | 0.72 | 0.72 |

| 2 | 0.63 | 0.71 |

| 3 | 0.38 | 0.68 |

| 4 | 0.20 | 0.63 |

| 5 | 0.11 | 0.53 |

| 6 | 0.07 | 0.38 |

| 7 | 0.05 | 0.26 |

| 8 | 0.04 | 0.19 |

It may be noted that a hinged end spring is one which is supported on pivots at both ends as in the case of springs having plain ends whereas a built-in end spring is one in which a squared and ground end spring is compressed between two rigid and parallel flat plates.

To avoid the buckling of the spring, it is either mounted on a central rod or located on a tube. When the spring is located on a tube, the clearance between the tube walls and the spring should be kept as small as possible, but it must be sufficient to allow for an increase in spring diameter during compression.

This is all about the Buckling of Compression Springs. Let us know what you think about this article in the comment section below.

Leave a Reply