In the previous article, we had an introduction to the piping systems, Piping applications, Piping Material selection, Pipe Joints, Pipe Fittings, and Piping system standards. Among the different Piping standards, One of the most used standards for the piping system is ASME B31. Which regulates the design, material selection, inspection, test, and safety of the Piping systems for all the applications. In this article, we are going to discuss different ASME Codes for Piping System.

Usually, the piping system includes pipe dimensions, flanges selection, and design, bolting, gaskets, use of valves, relief devices, fittings, and the pressure containing parts of other piping components.

This piping system also includes hangers and supports, and other equipment items necessary to prevent over-stressing the pressure-containing parts.

Support structures such as frames of buildings, buildings stanchions, or foundations are not considered as part of the Piping system.

Different Standards for Piping System

ASME(American Society of Mechanical Engineers) also known as ANSI and that is the most used standard among the other standards. Following are other standards that regulate the piping system as well.

- ASTM (A252) – American Society for Testing and Materials

- API (5L)- American Petrolium Institute

- EN (13480) – European metallic industrial piping code

- GOST – Russian National Standards

- AWS – American Welding society

- AWWA – American Water works association

- ANSI – American national Standard Institute

- CWB – Canadian Welding Beuro

The use of the above standards varies based on geographical location.

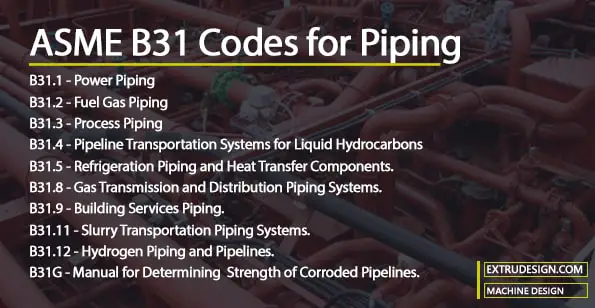

ASME Codes for Piping System

In ASME B31 we have different codes further according to the different application sectors as mentioned below.

| Code | Description |

| ASME B31.1 | Power Piping |

| ASME B31.2 | Fuel Gas Piping |

| ASME B31.3 | Process Piping |

| ASME B31.4 | Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids. |

| ASME B31.5 | Refrigeration Piping and Heat Transfer Components. |

| ASME B31.8 | Gas Transmission and Distribution Piping Systems. |

| ASME B31.8S | Managing System Integrity of Gas Pipelines. |

| ASME B31.9 | Building Services Piping. |

| ASME B31.11 | Slurry Transportation Piping Systems. |

| ASME B31.12 | Hydrogen Piping and Pipelines. |

| ASME B31G | Manual for Determining Remaining Strength of Corroded Pipelines. |

ASME B31.1 – Power Piping

Application Sectors: Industrial plants and Marine applications.

Applications: electric generation stations, industrial institutional plants, central and district heating plants, power boilers and high temperature(exceeding 250 degrees F), high-pressure(more than 15 PSIG of water pressure, 106PSIG steam pressure) water boilers.

Code Prescription: Designing, Material selection, erection, Testing, and inspections for the piping system

Code Document: ASME B31.1 Pdf file

ASME B31.2 – Fuel Gas Piping

Application Sectors: Gas Transmission and Distribution Piping System

Applications: Gas piping systems

Code Prescriptions: Design, Fabrication, Installation, and Testing of piping systems.

Code Gude: ASME B31.2 Pdf file not available

ASME B31.3 – Process Piping

Application Sectors: chemical, petroleum plants

Applications: Petroleum refineries; chemical, pharmaceutical, textile, paper, semiconductor, and cryogenic plants; and related processing plants and terminals.

Code Prescription: Material selection, Designing, assembly, erection, Testing, and inspections for the piping system.

Code Document: ASME B31.3 Pdf file

ASME B31.4 – Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

Application Sectors: Natural gas processing plants, refineries, stations, Ammonia plants, terminals (marine, rail, and truck).

Applications: Primary and associated auxiliary liquid petroleum and liquid anhydrous ammonia piping at pipeline terminals (marine, rail, and truck), tank farms, pump stations, pressure reducing stations and metering stations, including scraper traps, strainers, and proper loops; Storage and working tanks including pipe-type storage fabricated from pipe and fittings, and piping interconnecting these facilities, Liquid petroleum and liquid anhydrous ammonia piping located on the property which has been set aside for such piping within petroleum refinery, natural gasoline, gas processing, ammonia, and bulk plants.

Code Prescription: Material selection, Designing, assembly, erection, Testing, and inspections for the piping system.

Code Document: ASME B31.4 Pdf file

ASME B31.5 – Refrigeration Piping and Heat Transfer Components

Application Sectors: Refrigeration Piping and Heat Transfer Components

Applications: Refrigirent inspection, heat transfer components, and secondary coolant piping for temperatures as low as -320 °F (-196 °C), whether erected on the premises or factory assembled

Code Prescription: Material selection, Designing, assembly, erection, testing, and inspections for the piping system.

Code Document: ASME B31.5 Pdf file

Code Exemption: Any self-contained or unit systems subject to the requirements of Underwriters Laboratories or another nationally recognized testing laboratory: Water piping and piping designed for external or internal gauge pressure not exceeding 15 psi (105 kPa) regardless of size; or Pressure vessels, compressors, or pumps, but does include all connecting refrigerant and secondary coolant piping starting at the first joint adjacent to such apparatus.

ASME B31.8 – Gas Transmission and Distribution Piping Systems

Application Sectors: Gas Transportation

Applications: Pipeline Facilities used for the transportation of gas.

Code Prescription: Designing, Material selection, installation, testing, and inspections for the piping system.

Code Document: ASME B31.8 Pdf file

ASME B31.8S – Managing System Integrity of Gas Pipelines

Application Sectors: Gas Transportation

Applications: Pipeline Facilities used for the transportation of gas. This means all parts of physical facilities through which gas is transported, including pipe, valves, appurtenances attached to the pipe, compressor units, metering stations, regulator stations, delivery stations, holders, and fabricated assemblies.

The principles and processes are applicable to all pipeline systems. This Standard is specifically designed to provide the operator (as defined in section 13) with the information necessary to develop and implement an effective integrity management program utilizing proven industry practices and processes. The processes and approaches within this Standard are applicable to the entire pipeline system.

Code Prescription: Designing, material selection, installation, testing, and inspections for the piping system.

Code Document: ASME B31.8S Pdf file

ASME B31.9 – Building Services Piping

Application Sectors: industrial, institutional, commercial, and public buildings, and multi-unit residences.

Applications: Pipeline facilities used in the industrial, institutional, commercial, and public buildings, and multi-unit

residences, which does not require a range of sizes, pressures, and temperatures covered in ASME B31.1.

Code Prescription: Designing, Material Selection, installation, testing, and inspections for the piping system.

Code Document: ASME B31.9 Pdf file

ASME B31.11 – Slurry Transportation Piping Systems

Application Sectors: Plants and terminals, pumping and regulating stations which transport Slurry.

Applications: Piping transporting aqueous slurries of nonhazardous materials, such as coal, mineral ores, concentrates, and other solid materials.

Code Prescription: Designing, Material Selection, installation, testing, and inspections for the piping system.

Code Document: ASME B31.11 Pdf file

ASME B31G – Manual for Determining Remaining Strength of Corroded Pipelines

Application Sectors: This B31G code is applicable to all sectors that are part of the ASME B31 Code for Pressure Piping.

Applications: This B31G code is applicable to all pipelines and piping systems that are part of the ASME B31 Code for Pressure Piping.

Code Prescription: Designing, Material Selection, installation, testing, and inspections for the piping system.

Code Document: ASME B31G Pdf file

Copyright: This article ASME codes for the piping system is only for educational purposes. The above-mentioned PDF links are provided for educational purposes only. The original content remains the property of the respective Owner.

okay good