A spring is defined as an elastic body, whose function is to distort when loaded and to recover its original shape when the load is removed. It absorbs or controls energy due to either shock or vibration so it can be used as shock absorbers and vibration dampers. It is also used to apply forces, as in brakes, clutches, and spring-loaded valves. We have already discussed different types of springs in the previous article. Let us discuss what are the Helical Torsion Springs.

Applications of Springs

The various important applications of springs are as follows:

- To cushion, absorb, or control energy due to either shock or vibration as in car springs, railway buffers, aircraft landing gears, shock absorbers, and vibration dampers.

- To apply forces, as in brakes, clutches, and spring-loaded valves.

- To control motion by maintaining contact between two elements as in cams and followers.

- To measure forces, as in spring balances and engine indicators.

- To store energy, as in watches, toys, etc.

Types of Springs

Though there are many types of springs, the following, according to their shape, are important from the subject point of view.

- Helical springs

- Conical and volute springs

- Torsion springs

- Laminated or leaf springs

- Disc or Belleville springs

- Special-purpose springs

We have discussed more details in a separate article here!

Helical Torsion Springs

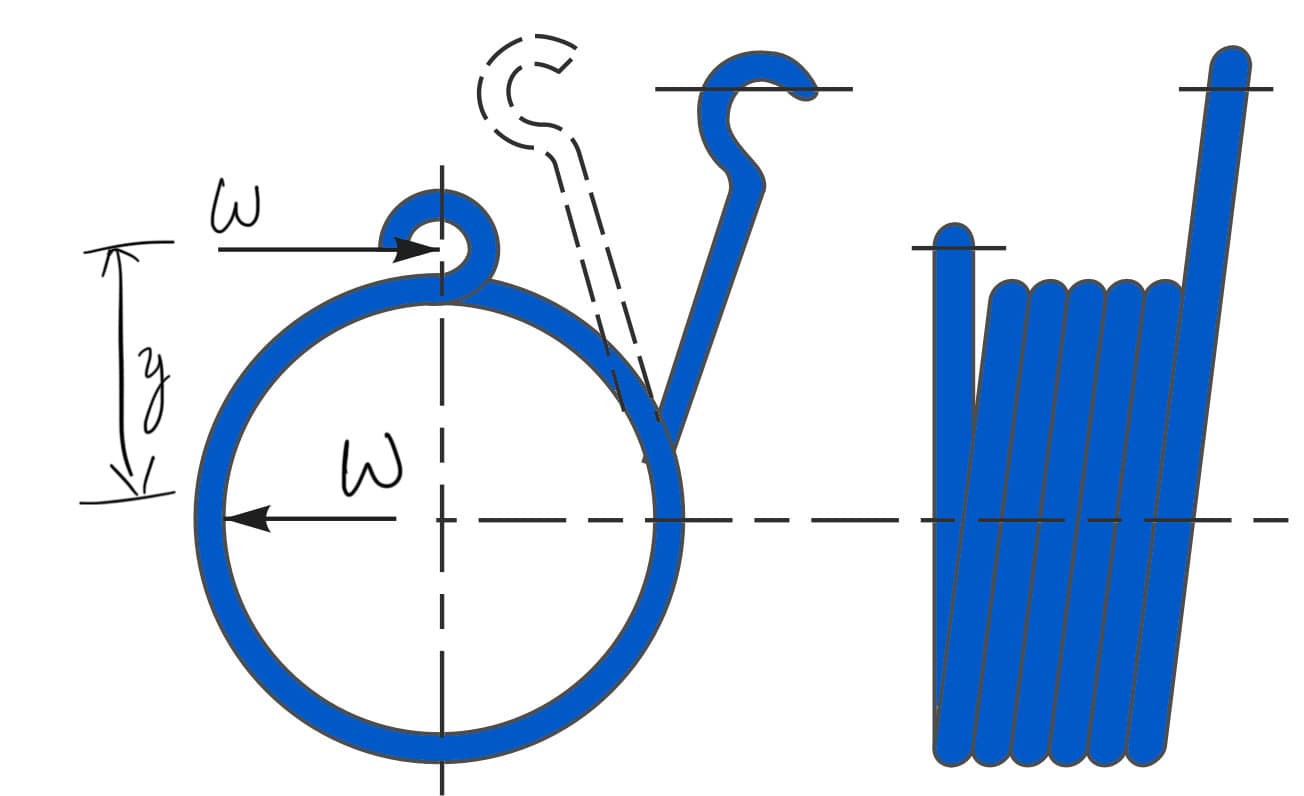

The helical Torsion Spring is a combination of Helical spring and Torsion spring. The helical torsion springs as shown in the following figure, may be made from round, rectangular, or square wire. These are wound in a similar manner as helical compression or tension springs but the ends are shaped to transmit torque.

The primary stress in helical torsion springs is bending stress whereas in compression or tension springs, the stresses are torsional shear stresses. The helical torsion springs are widely used for transmitting small torques as door hinges, brush holders in electric motors, automobile starters, etc.

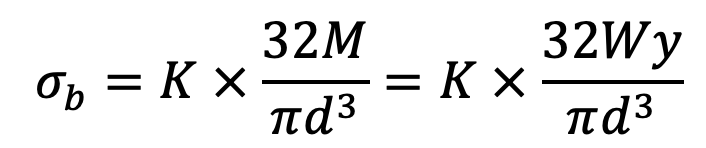

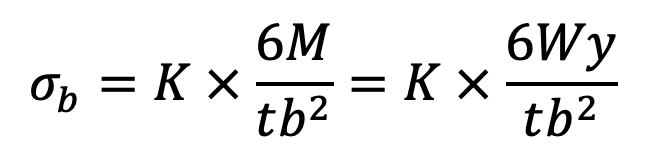

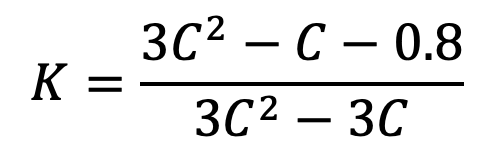

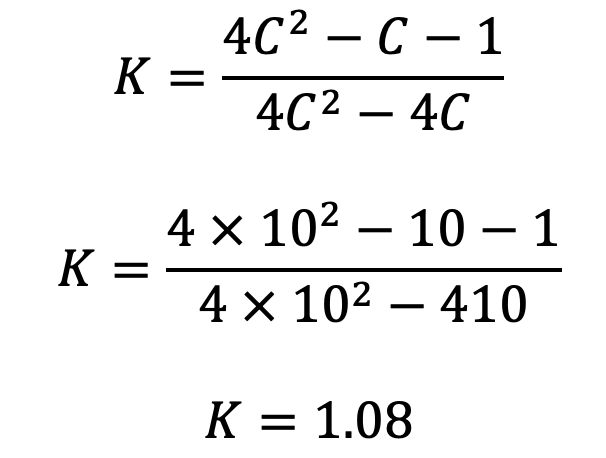

A little consideration will show that the radius of curvature of the coils changes when the twisting moment is applied to the spring. Thus, the wire is under pure bending. According to A.M. Wahl, the bending stress in a helical torsion spring made of round wire is

Where

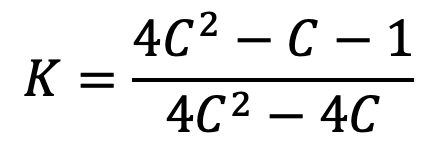

K = Wahl’s stress factor

C = Spring index

M = Bending moment = W × y

W = Load acting on the spring

y = Distance of load from the spring axis

d = Diameter of spring wire

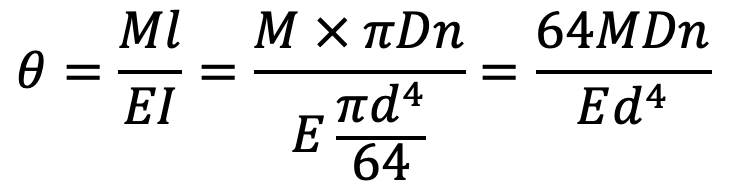

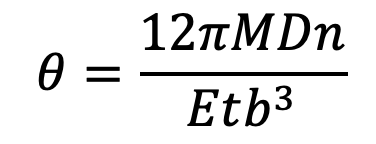

and total angle of twist or angular deflection,

Where

l = Length of the wire = π.D.n

E = Young’s modulus

I = Moment of inertia

D = Diameter of the spring

n = Number of turns

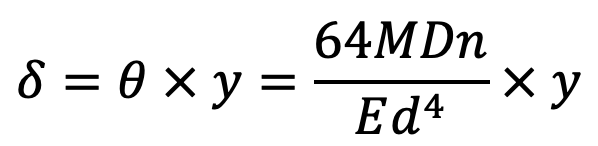

and the deflection,

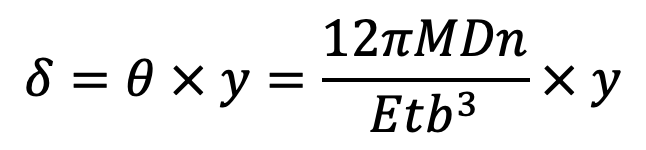

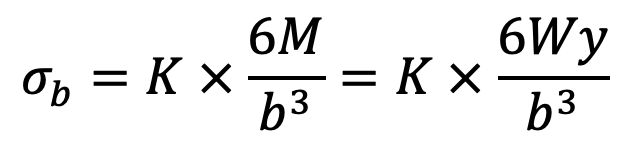

When the spring is made of rectangular wire having width b and thickness t, then

where

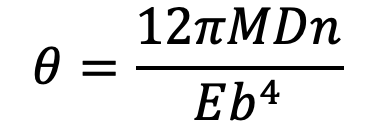

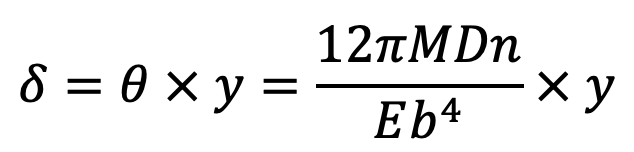

Angular deflection,

and deflection,

In case the spring is made of square wire with each side equal to b, then substituting t = b, in the above relation, we have

Angular deflection,

and deflection,

Since the diameter of the spring D reduces as the coils wind up under the applied load, therefore a clearance must be provided when the spring wire is to be wound round a mandrel. A small clearance must also be provided between the adjacent coils in order to prevent sliding friction.

How to calculate bending stress and angular deflection in Helical Torsion Springs?

Problem Statment: A helical torsion spring of mean diameter 60 mm is made of a round wire of 6 mm diameter. If a torque of 6 N-m is applied on the spring, find the bending stress induced and the angular deflection of the spring in degrees. The spring index is 10 and modulus of elasticity for the spring material is 200 kN/mm2. The number of effective turns may be taken as 5.5.

Answer:

Given data:

Mean Diameter of the Spring D = 60 mm

wire diamter d = 6 mm

Applied torque / moment M = 6 N-m = 6000 N-mm

Spring index C = 10

modulus of elasticity E = 200 kN/mm2 = 200 × 103 N/mm2

Number of effective turns n = 5.5

Bending stress induced in Helical Torsion Spring

We know that Wahl’s stress factor for a spring made of round wire,

Bending stress induced

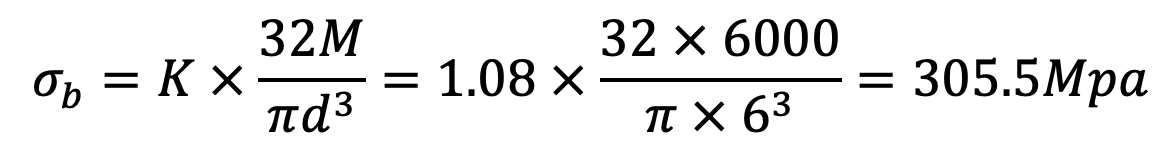

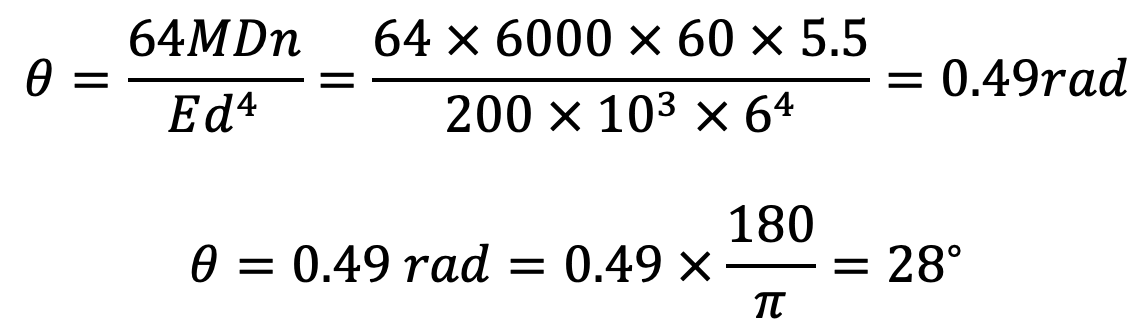

Angular deflection of the spring

We know that the angular deflection of the spring (in radians),

This is all about the Helical Torsion Springs. Let us know what you think about this article in the comment section below.

Leave a Reply