In metrology, the Surface plate is used as a measuring base or a datum surface for testing of flatness of surfaces. Surface plate forms the basis of the measurement. Surface plates are widely used in where the inspection is carried out. We are going to discuss What is Surface Plate? Uses of Surface Plate, material construction of surface plate.

The surface plate is a massive solid structure, highly rigid in design which is having a true flatness of the surface.

Construction of Surface Plates

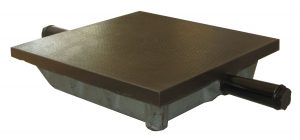

The surfaces plates are made up of Cas iron(C.I) and heat treated for relieving internal stresses. the top face of the surface plate is designed as truly flat. The back side of the surface plates is having ribs to increase the structural rigidity to withstand the heavy loads.

see the picture how the ribs are arranged to make it stronger.

This surface gauge is supported by levelling screws to make sure to adjust the surface plate to be truly horizontal.

Required Material Properties

To make a perfect surface plate, the material should have the following requirements.

- Should have the high degree of rigidity

- taking high surface finish, resistance to the wear and corrosion

- free from warping (warping meant become Twisted)

Materials used to make Surface Plates

- Cast Iron (C.I)

- Granite

- Glass

Cast Iron Surface plate / C.I Surface Plates

Cast Iron is the most commonly used material to made surface plates. Cast iron delivers the best surface plates over the other materials. Heat treatment and annealed in order to relieve the internal stresses. Cast iron Surface plates are allowed for a certain amount of warping when a sudden load is taking place on the surface plates.

Granite Surface Plates

Granite surface plates are best known for the rustless surface plates. Granite surface plates are able to unaffected with the temperature changes and Heat so that it can maintain the flatness for longer life. The hardness of the granite surface plates is more than the C.I Surface Plates.

Glass Surface Plates

Surface plates can be made up of the Glass as well. The main reasons to make the surface plates from the glass is due to the following reasons.

- Weight reduction

- Avoid corrosion and burrs

- Archive high accuracy and Maintain it for longer life

But they need to be handled carefully they can be broken. Ceramic Surface plates are using nowadays.

Precautions need to take while using the Surface Plates

- The flatness should be checked occasionally to make sure the surface is in perfect condition to use.

- Keep the measuring instruments away from the surface plate, They shouldn’t be dropped on the surface of the plate, may cause damage.

- The top surface must be cleaned before use to avoid the dust and other particles.

- They should be covered with the Wooden cover when they are not in use

- Try to use the all-area instead of a particular area each time so the wear of the surface plate will be uniform over the time.

- After usage of the surface plate, the top flat face should be coated with the corrosion resistance(Oil or Grease).

Want to know how true the flatness of the surface plate?

Read this article Testing Flatness of Surface Plates

Leave a Reply