Topic: What is Machine Design Procedure? | General procedure in machine design | Steps Involved in machine design

In Mechanical Engineering, Machine Design is subjected to creating new or Advanced machines. This involves improving the existing machines to better machines.

The Machine design procedure will require so many factors need to be considered. These factors we can call them as the steps or a procedure.

There are several steps involved in designing a machine either it is a new machine or an existing one or it can be the development of the existing machine.

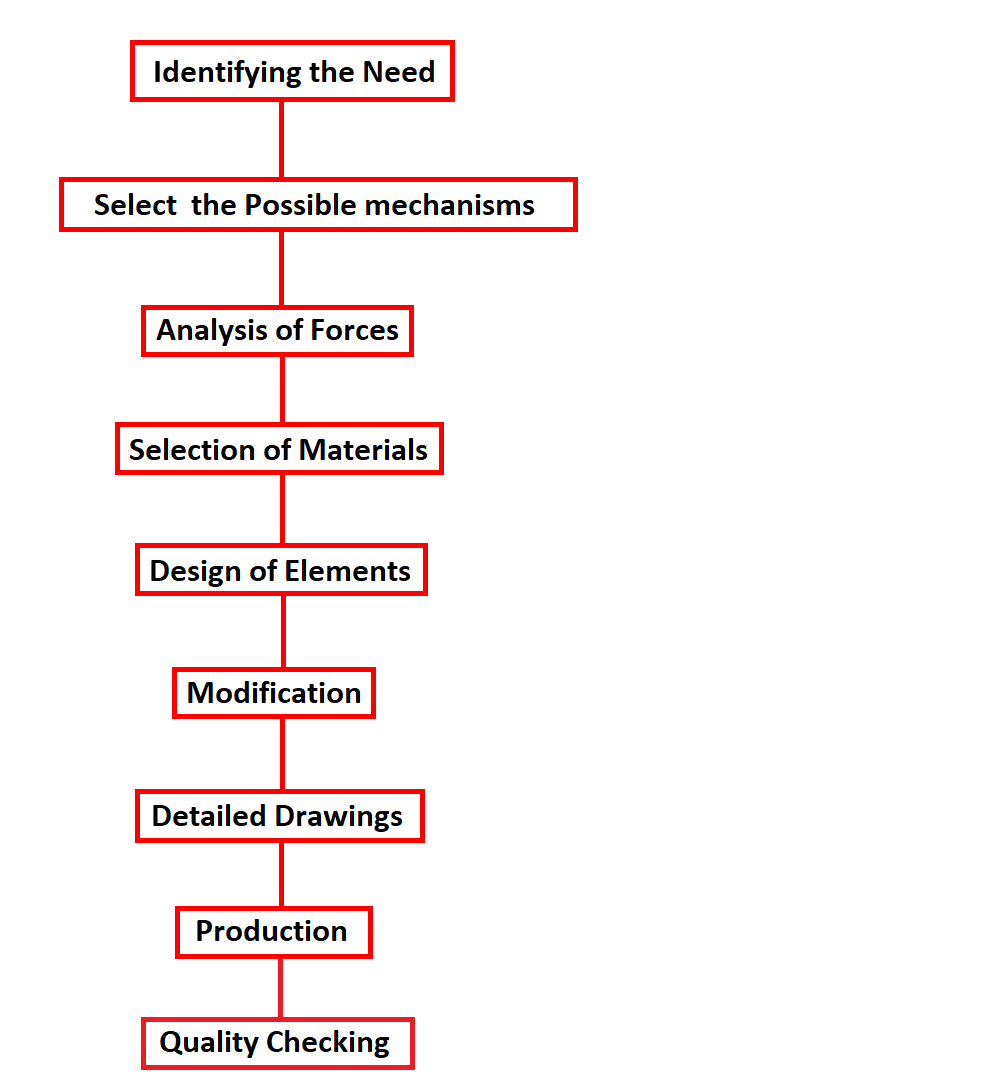

Let’s see the different steps involved in the machine design/Machine design Procedure / General Procedure in machine design with the following schematic diagram

Machine Design Procedure

- Identifying the need for the Equipment or a Machine

- Selecting the possible Mechanisms

- Analysis of Forces

- Selection of Materials

- Design of Elements

- Modification

- Detailed Drawings

- Production

- Quality Checking

Identifying the need for the Equipment or a Machine

Recognising the solution for a problem by giving a complete statement of the problem by identifying the aim and purpose of why the machine is needed to be designed.

Selecting the possible Mechanisms

Synthesise the different mechanism and choose the best mechanism for the required motions among the different mechanisms

Analysis of Forces

Analyse the different system of forces in the motion of the machine members and power transmissions among the different machine elements.

Selection of Materials

Select the best-suited materials for the different components in the machine and we should keep an eye on the availability of the materials as well.

Design of Elements

We should design a machine that should accept the operation conditions as well as it should withstand for a longer life.

For that, we need to analyse the size and stresses acting in different elements in the machine by considering the forces acting on the machine elements. we should check these stresses with the permissible stress of each material we have used in the making of machine elements.

Modification

To reduce the overall cost of the productions and due to the availability of the resources, we should make some considerations to accommodate the changes. we should modify the size or any other modification needs to happen. this is the case we need to be ready to do modification in the design.

Detailed Drawings

We can say this is the final stage for determining what kind of machine we are going to build. Once we have done with the detailing of each and every components and assembly and subassemblies drawings, we should proceed with the manufacturing.

Production

As per the drawing, the components will be manufactured in the manufacturing units. and assembled as per the detailed drawings. her everything will be produced and sent them to the next step quality checking(QC). If any difference is there then it should come back for the reproduction.

Quality Checking

This is the final step to determine whether the production of each machine element is as per the detailed drawings we have provided.

This is the machine design procedure

Also, read about Machine Design Classification

Tags: What is Machine Design Procedure? Machine Design, Engineers guide to machine design, Steps involved in Machine design, Mechanical Engineering Basics, Machine Design Procedure

usefull discription👍

Glad you like it