The drilling process means making a hole in a solid metal piece by using a rotating tool called a drill. In this article, we will discuss how this drilling machine works and also different types of Drilling machines. With the Drilling machine, many other operations also can be done apart from drilling holes.

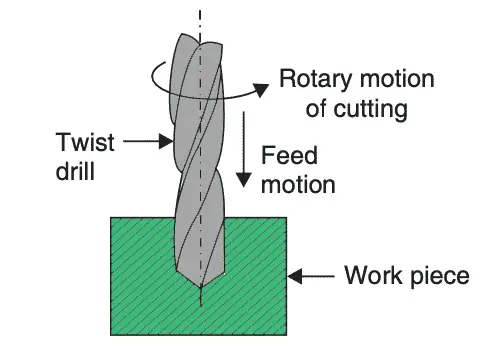

In the olden days, a flat drill was used for drilling a hole, but these days, a twist drill is universally used. A twist drill is the cutting tool and it is used in conjunction with a drilling machine. A twist drill has two cutting edges, hence it is a multiple point cutting tool. The drilling operation is shown in the following figure.

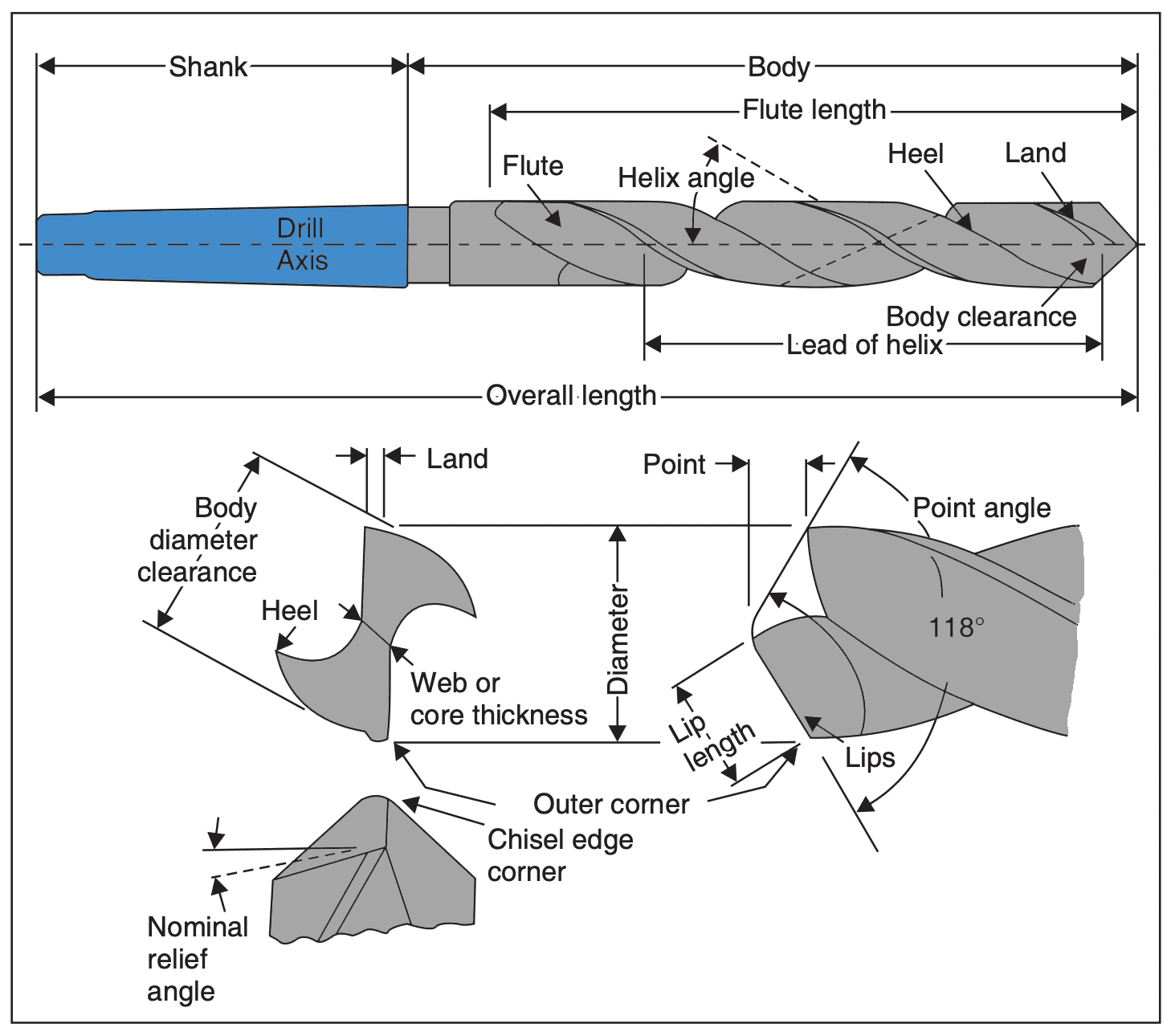

Twist Drill

Twist drills usually have a tapered shank, at the end which is fitted into the drilling machine having a tapered sleeve of matching taper. When the tapered sleeve rotates, the twist drill also rotates along with it due to the friction between two tapered surfaces. Sometimes the shank is machined parallel, and then a special collet chuck is fitted in the drilling machine, in which the drill is held.

A twist drill is shown duly labelled in the following figure.

The drill has two lips at the other end where the cutting takes place when the drill rotates. The angle between the two cutting lips is usually 118°. The chips formed at the cutting edges are automatically guided upwards through the helical grooves cut into the body of the drill; these grooves are called flutes. This is necessary, otherwise, the chips will interfere with the metal cutting.

Drilling Operation

For rotating the drill and to overcome the resistance in cutting, a torque is needed to rotate the drill. An axial force is also needed which keeps pushing the drill deeper and deeper into the hole being drilled. The machine feed provides this. Machine feed is the downward axial movement of the drill per revolution of the drill.

The drill will not start cutting the metal if its bottom touches the metal surface superficially. This is on account of the chisel edge which does not allow the cutting edges to come into the contact with metal and start cutting until the chisel edge penetrates the metal surface by about an mm or so. To facilitate the cutting action, a little depression is made by a punch at the centre of the hole to be drilled. Twist drills are made of solid high-speed steel, hardened and ground to shape. Drills with tungsten carbide inserts are also available.

Drilling Machines Types

Following are the different types of Drilling machines:

- Sensitive drilling machines

- Pillar type drilling machines

- Radial drilling machines

- Multispindle drilling machines

1. Sensitive Drilling Machines

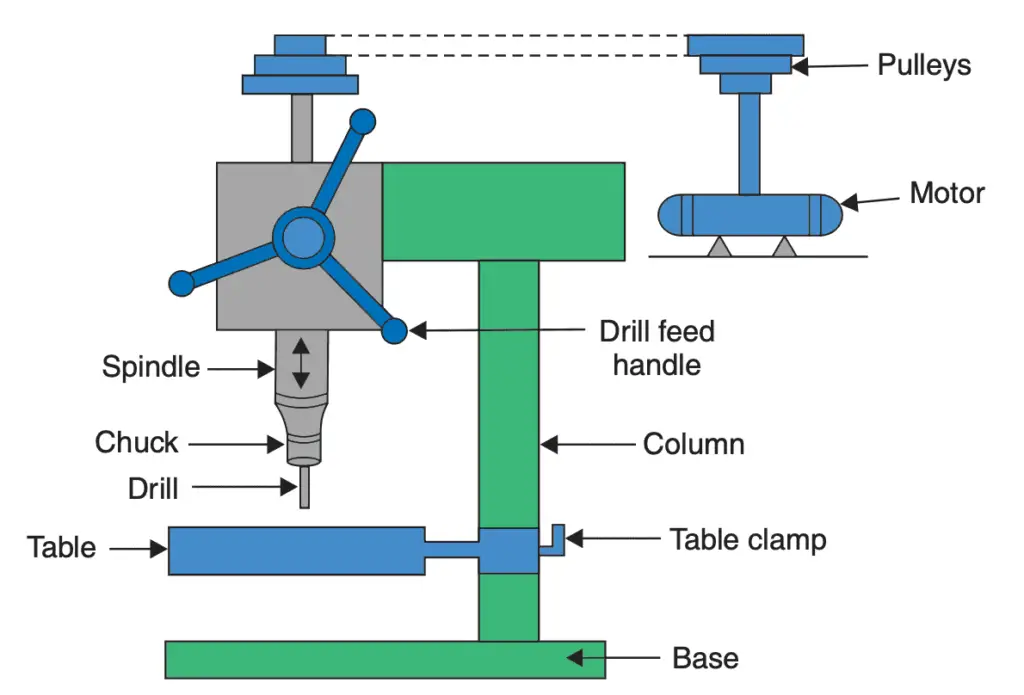

A sensitive drilling machine is shown in the following figure.

This is a light-duty machine and is capable of drilling a hole of 12 mm dia maximum and its spindle speeds are correspondingly high. This machine can tackle small jobs. The workpiece is kept on the table and clamped in the appropriate position and the hole is drilled by lowering the spindle of the drilling head. Feed is given by moving the handwheel gently which lowers the spindle and the hole is drilled up to the required depth. Remember that the job has to be moved so as to align the centre of the hole exactly below the spindle.

2. Pillar Type Drilling Machines

These are generally similar to sensitive drilling machines but are meant for heavier work. The vertical column can be either of rectangular or round section; the latter offers the advantage that the table can be swung out and the slightly bigger jobs can be accommodated on the machine base instead of the table. The drilling head can be lowered and a hole drilled in the job.

3. Radial Drilling Machine

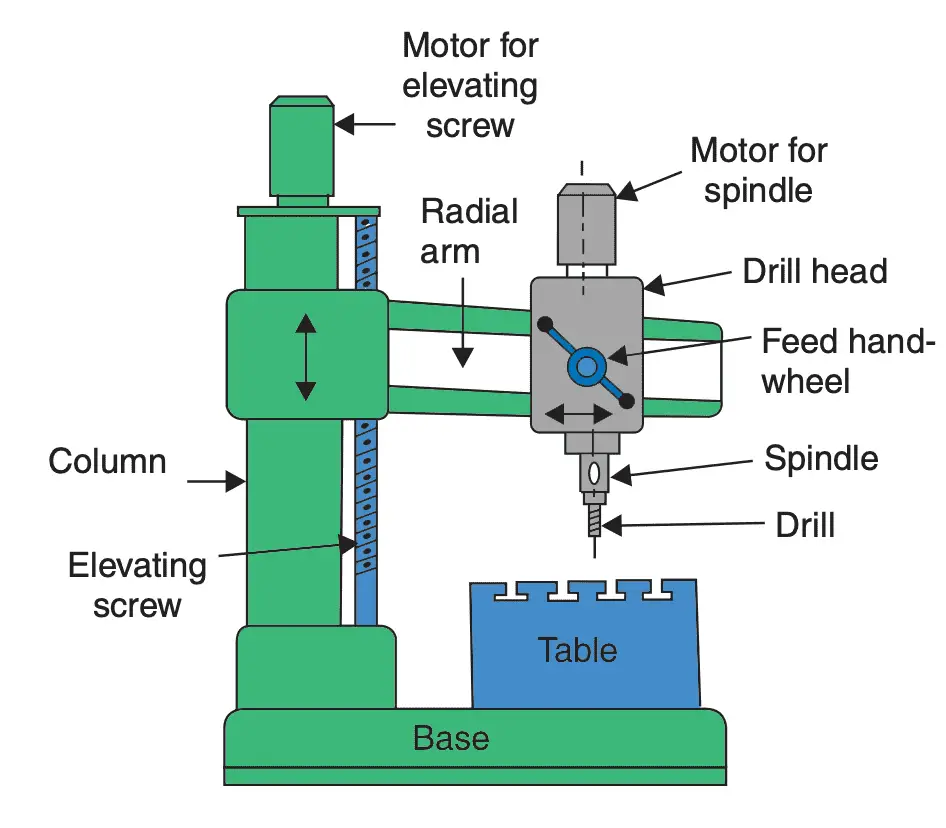

A radial drilling machine is illustrated in the following figure. This is really meant to drill holes in bigger and heavier workpieces, which cannot be manipulated so that the centre of the hole may be aligned with the drilling spindle. In this case, the drilling head is mounted on a radial arm. The radial arm can be rotated around the round column and the drilling head can be moved in or out on the radial arm.

The workpiece is kept on the table which is really an integral part of the base and by the combined movement of the radial arm and the drilling head (think of the polar coordinates θ, r), any point on the workpiece can be covered and a hole drilled at the required location, without shifting the heavy workpiece.

4. Multiple Spindle Drilling Machines

On these machines, more than one hole may be drilled at one time. These machines are very useful for mass production work.

Different other Operations Performed On Drilling Machines

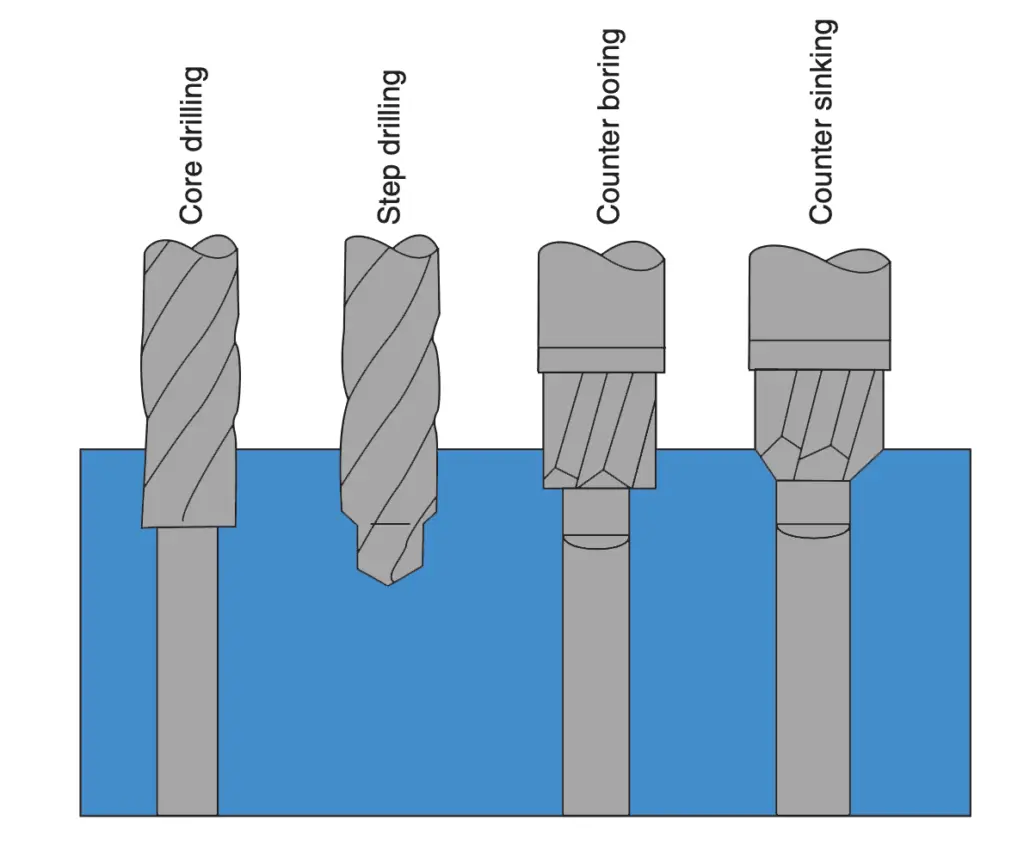

Operations closely associated with drilling are shown in the following figure.

Core drilling

Holes made in castings by use of cores, are rough and require a special kind of drill, called a core drill to clean up the holes. This operation is called core drilling.

Step drilling

More than one diameter can be ground on the drill body which saves an extra operation.

Counter boring

Often a flat surface is needed around a hole to provide a good seating area for the washer and nuts/head of a bolt. The counterboring tool has a pilot, which ensures that the counterbore is concentric with the hole.

Countersinking

Countersinking provides a tapered entrance to the hole. A special countersinking tool with a pilot is used as shown.

Reaming

Reaming is an operation of sizing and improving the geometry and finish of a previously drilled hole. Hand, machine and shell reamers are used for this purpose. Machine reamers are used with a drilling machine. To work efficiently, proper stock allowance is very important. Reamers cannot remove much material, but at the same time, enough material should be available all around. For holes up to 12.5 mm in diameter, about 0.38–0.4 mm of material is left as reaming allowance. A reamer follows the original hole and cannot shift its centre.

Tapping

Tapping is also done on a drilling machine with a special flexible adapter for holding machine taps. Tapping means cutting internal threads in a hole. A machine tap set consists of two taps rough and finish. Both taps should be used in the same order. During tapping, the spindle r.p.m. is drastically reduced and a good lubricant is used.

Conclusion

The drilling process means making a hole in a solid metal piece by using a rotating tool called a drill. We have discussed the different types of drilling machines Sensitive drilling machines, Pillar type drilling machines, Radial drilling machines and Multispindle drilling machines and also discussed the different other operations performed with the Drilling machine such as core drilling, step drilling, counter bearing, reaming and tapping. Let us know what you think about this article in the comment section below.

very helpful and informative article is this,

May everyone can increase their drilling experience if they follow the post with full focus.

specially it is very important for me because my job is related to drill machine and i will use the drill on daily basis.

Thanks for sharing this information.