The Air Lift pump is a device which is used for lifting water from a well or sump by using compressed air. The compressed air is made to mix with the water. The Air Lift pump has no moving parts and relies on the difference in density between the air and water mixture and the surrounding fluid. Let us discuss more on Air Lift Pump working principle.

Fluid Systems

A fluid system is defined as a device in which power is transmitted with the help of a fluid which may be liquid (water or oil) or a gas (air) under pressure. Most of these devices are based on the principles of fluid statics and fluid kinematics. Following are the different devices that come under the Fluid systems.

- The hydraulic press

- The hydraulic accumulator

- The hydraulic intensifier

- The hydraulic Ram

- The hydraulic Lift

- The hydraulic Crane

- The fluid or hydraulic coupling

- The fluid or hydraulic torque converter

- The Air Lift pump

- The gear-wheel pump

Air Lift pump

The Air Lift pump is a device which is used for lifting water from a well or sump by using compressed air. The compressed air is made to mix with the water. The density of the mixture of air and water is reduced. The density of this mixture is much less than that of pure water. Hence a very small column of pure water

can balance a very long column of the air-water mixture. This is the principle on which the air lift pump works.

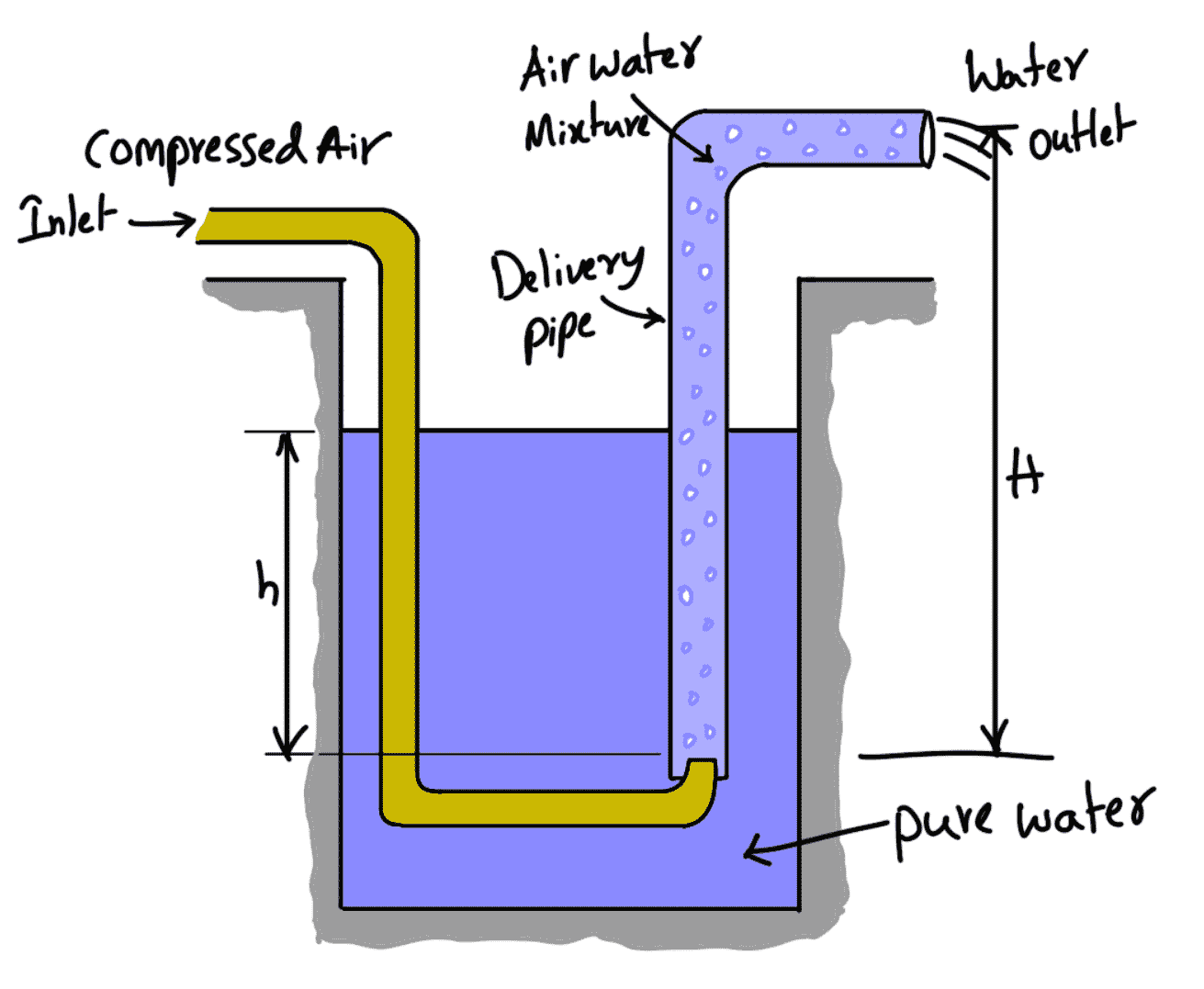

The above figure shows the Air Lift pump. The compressed air is introduced through one or more nozzles at the foot of the delivery pipe, which is fixed in the well from which water is to be lifted. In the delivery pipe, a mixture of air and water is formed. The density of this air-water mixture becomes very less as compared to the density of pure water. Hence, a small column of pure water will balance a very long column of the air-water mixture. This air-water mixture will be discharged out of the delivery pipe. The flow will continue as long as there is a supply of compressed air.

Let

h = Height of static water level above the tip of the nozzle,

H = Height to which water is lifted above the tip of the nozzle.

The (H – h) is known as the useful lift. The best results are obtained if the useful lift (H – h) is less than the height of static water (h) above the tip of the nozzle. Hence for best results, (H- h) should be less than h.

The ratio (h / (H-h)) generally varies from 4 to 1.

When h = 30m, the ratio (h / (H-h)) is about 4.

When h = 90m, the ratio (h / (H-h)) is about 1.

For h = 30m,

(h / (H-h)) = 4

(30 / (H-30)) = 4

30 + 120 = 4H

H = 37.5 m

The Air Lift pump is not having any moving parts below the water level and hence there are no chances of suspended solid particles damaging the pump. This is the main advantage of this pump. Also, this pump can raise more water through a borehole of a given diameter than any other pump. But the efficiency of this pump is low as out of the energy expended in compressing the air, only 20 to 40% of energy appears in the form of useful water horse-power.

Advantages of an Air Lift pump

- It has no moving parts and is resistant to abrasion and corrosion from sand or solids in the fluid.

- It is compact, lightweight and easy to install and operate.

- It is energy-efficient and uses existing air sources.

- It can handle large flow rates and aerate the fluid at the same time.

Disadvantages of an Air Lift pump

- It has low suction power and limited lifting height.

- It has low efficiency compared to other types of pumps.

- It may get blocked by solid impurities in the fluid.

Applications of Air Lift pump

- Pumping, circulating and aerating water in aquaculture systems and ponds.

- Dredging harbours and river beds and extracting mineral nodules from the sea bed.

- Collecting fauna samples from sediment and underwater archaeology.

- Pumping water from deep dirty wells and wastewater treatment plants.

This is all about the AirLift pump working, its advantages and its applications. Let us know what you think about this article in the comment section below.

Leave a Reply