In metal works, both shapers and planers are machine tools which produce a flat surface. Unlike the lathe machine, Shapers and Planers are capable of machining a horizontal, vertical or inclined flat surface. They employ single-point cutting tools which are essentially similar to single-point cutting tools used on a lathe. In both Shaper and Planer machine tools, the cutting tool is subjected to interrupted cuts, the tools cuts in the forwarding direction and the Workpiece is idle in the return direction. Let us discuss how the Shapers and Planers work in detail.

Shaping Machine

Shaper consists of a hollow machine bed made of cast iron which rests on the ground. Inside the hollow portion, the machine drive mechanism is housed. This mechanism is called a slotted lever quick return mechanism and it drives a horizontal ram which reciprocates in the guideways provided on the top surface of the machine frame.

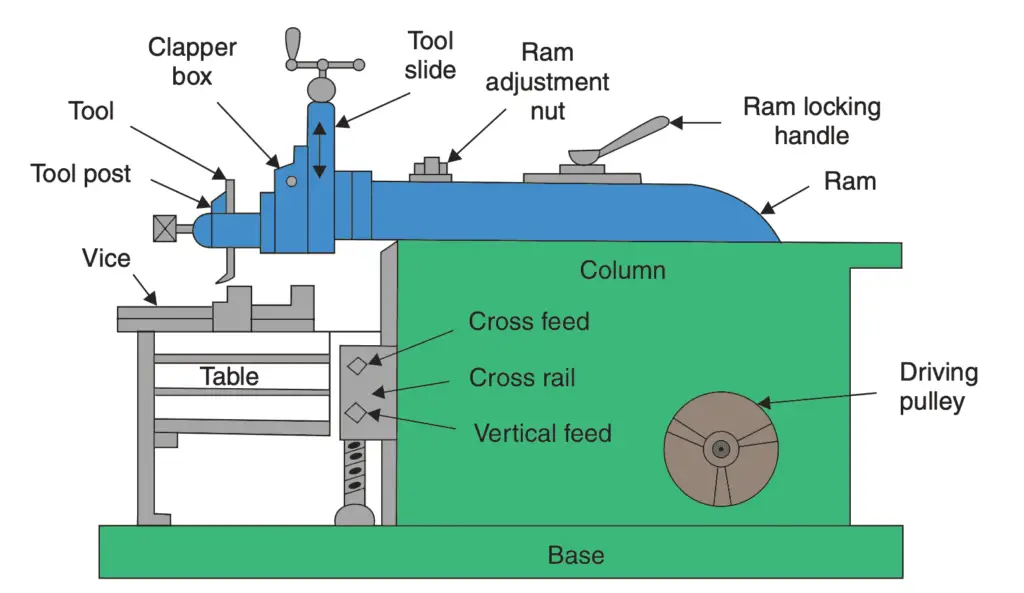

The detailed schematic diagram of the shaper is shown in the following figure.

The tool post is fitter in the front face of the ram as shown in the above figure. This is a very special kind of tool post. It carries a slide which can be operated by a hand wheel and the entire tool post can be lowered or raised. Besides, the tool slide can be swivelled in a vertical plane and its inclination to the vertical (amount of swivelling) can be read off on a scale marked in degrees. The tool is inclined when an inclined surface has to be machined.

In the front portion of the base, a table is fitted. The table can be raised or lowered to vary its height. It can also be moved horizontally to the left or right. A vice to hold the workpiece is provided on the tabletop.

The tool does useful work i.e., cutting only in the forward stroke of the ram. It does not cut i.e., it is idle during the return stroke of the ram. In order that while returning, the tool may not rub and spoil the strip of the metal machine in the forward stroke, a special device called the “clapper box” is provided in the tool post. It lifts the tip of the tool during the return stroke.

Quick Return Mechanism in Shaper Machine

Since useful work is done only during the forward stroke of the ram, the mechanism driving the ram is so designed that the return stroke is completed in much less time than the forward stroke. The slotted lever

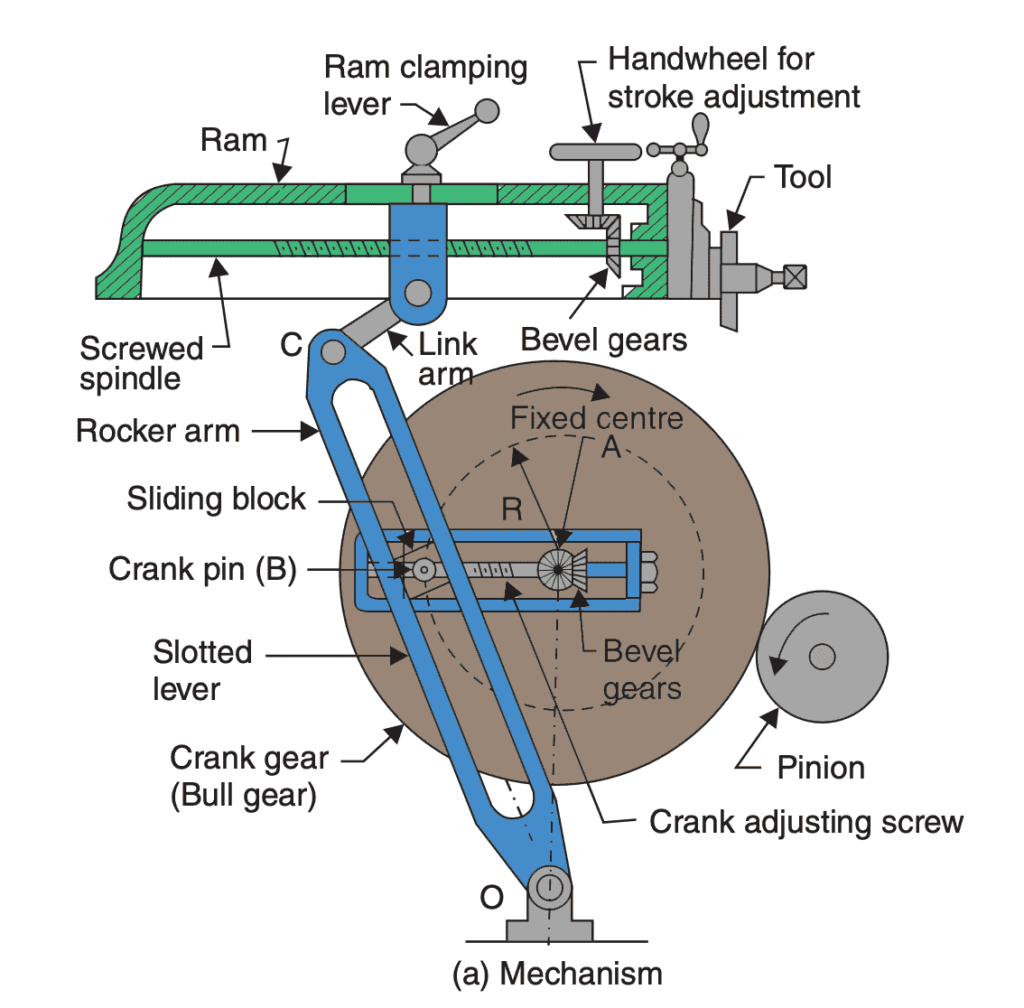

The quick return mechanism is illustrated in the following figure.

Working Principle of Quick Return Mechanism

Let us understand the principle of this Quick return mechanism in detail with the help of a free body diagram.

- The crank AB (of adjustable length R) rotates with a uniform angular speed.

- The crankpin B is in the shape of a die block which is free to slide inside the slot in the slotted lever OBC.

- This slotted lever is pivoted at O and the other end C is connected to the ram by a short link arm as shown in the above schematic diagram (a).

- When the crank AB rotates clockwise from position AB1 to AB2, the ram moves forward from left to right and when it rotates from position AB2 to AB1 the ram returns back to its original position.

- Clearly, the time taken to complete the forward stroke is proportional to angle α and the return stroke is completed in less time which is proportional to angle β.

Shaping Machine Cutting Tools

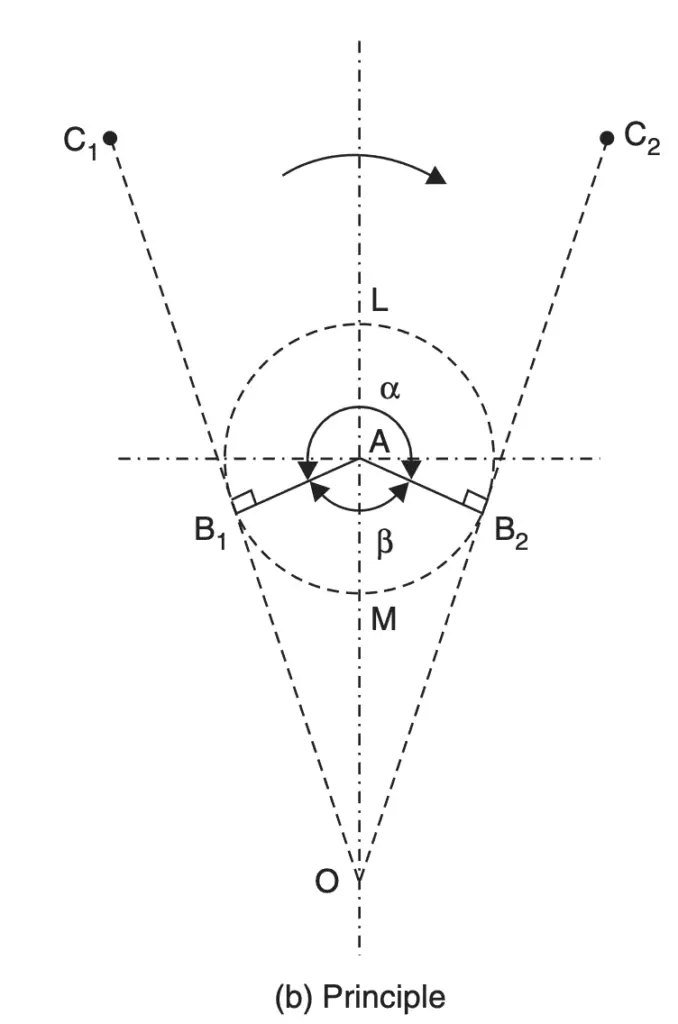

The cutting tools for shapers are generally made of H.S.S., either solid or with brazed tips. Due to interrupted cuts, tungsten carbide tools are not preferred for shaping work. These tools are made sturdy

with fairly generous size for shank and tip. Various types of tools useful for shaping are shown in the following figure.

Operations Performed On Shapers

On a shaping machine, relatively small jobs can be machined. The size of a shaper is denoted by the maximum length of stroke of its ram and workpieces longer than the maximum stroke cannot be

machined.

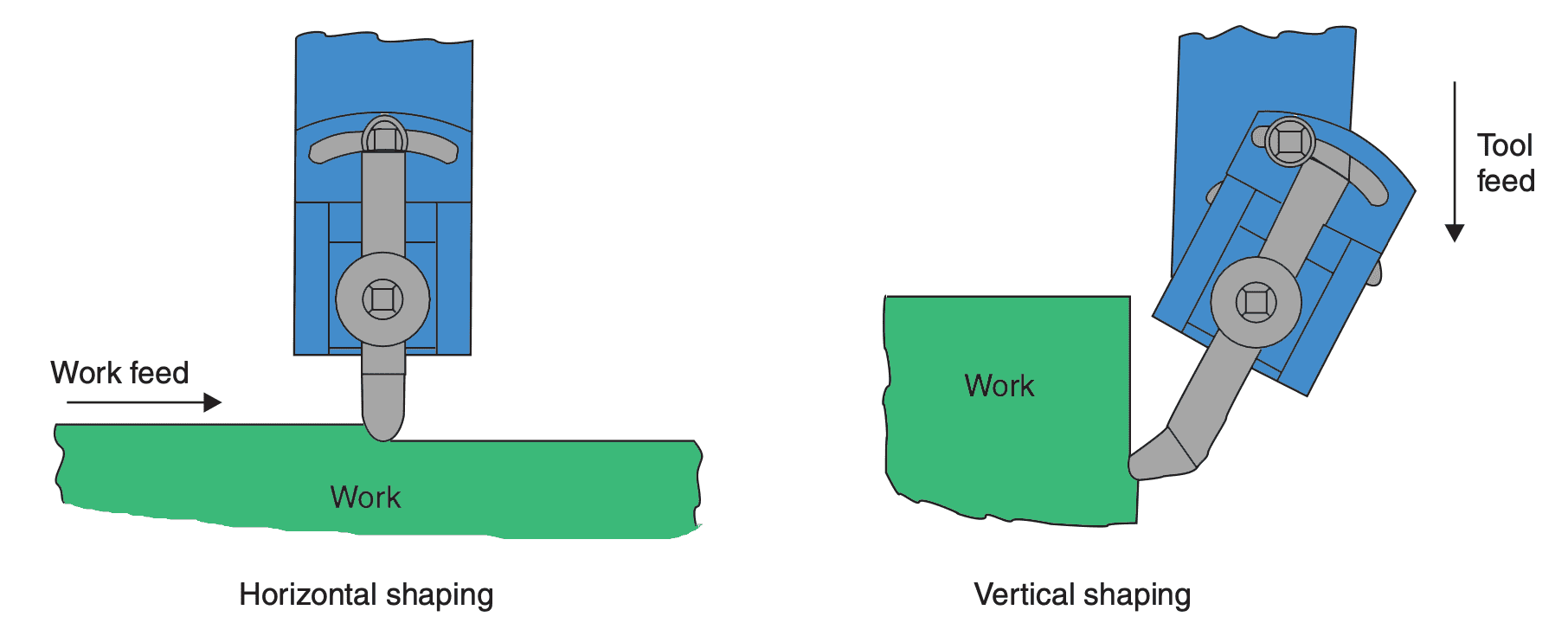

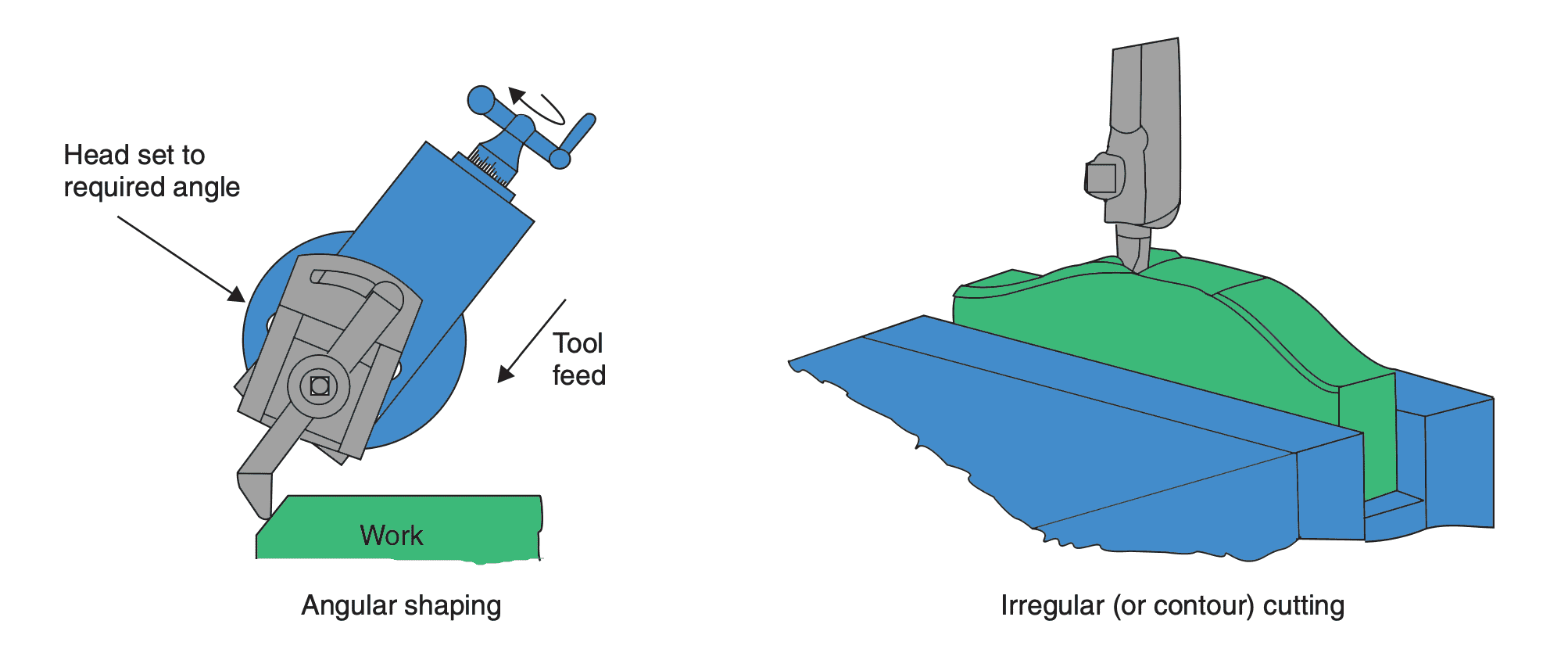

Operations performed on a shaper can be easily understood from the following figure.

- The first step in machining a job is to mount the job on the shaper-table and clamp it tightly in the vice or on the table by means of T-bolts etc.

- The second step is to adjust the stroke of the ram according to the length of the workpiece.

- The ram stroke is kept about 60–70 mm longer than the job.

- The stroke can be reduced or increased by altering the length of the crank AB.

- Now by changing the position of the location where the short link arm is connected to the ram, the stroke is made to overlap the job.

- So that the stroke starts 30–35 mm before the job and covers the whole length of the workpiece and ends 30–35 mm beyond it.

- A tool is now selected and clamped in the tool post.

- The depth of cut is given by rotating the handwheel and lowering the tool slide.

- Depth of cut is not given by raising the table height.

- Table height is adjusted only at the time of fixing the job according to the height of the job.

- Feed is given by shifting the table laterally.

- The feed to the table can be given either manually or automatically.

- The feed is given during the return stroke of the ram.

Contour cutting is a very skilful job as it calls for simultaneous operation of horizontal table feed as well as vertical hand feed of the cutting tool. It can be performed only by a very skilled operator.

Planning Machine

Planer has been used for machining flat surfaces on workpieces, which are too large and heavy to be accommodated on a shaping machine table. The fundamental difference between a planer and a shaper is that in a planer, the cutting tool remains stationary and the planer table on which the workpiece has been clamped moves past the cutting tool. The feed is given to the cutting tool and not to the table which reciprocates in the guideways provided in the machine bed.

A planer can handle much heavier cuts and more than one tool post is provided on one machine so that machining can be done quickly. Sometimes a horizontal surface and a vertical surface are machined simultaneously and the squareness of the surfaces is automatically ensured.

Planning Machine Working Principle

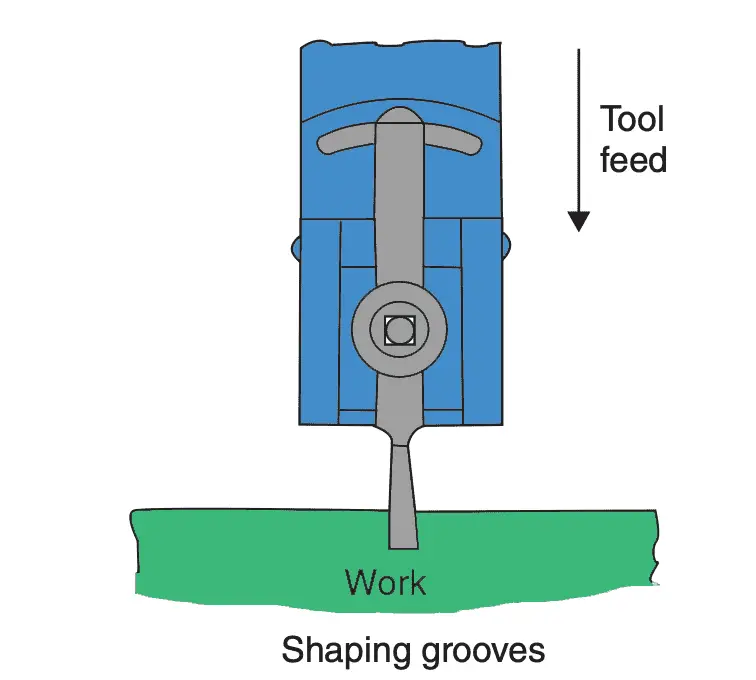

- The planer consists of a sturdy bed made of cast iron, on the upper surface of which Veeguideways have machined all along the length of the bed.

- The base of the bed is grouted in the ground.

- The table is again made of cast iron having matching guideways machined at its bottom so that it can slide longitudinally on the machine bed.

- The table has a long rack machined in the centre of its width which is used for giving reciprocating motion to the table.

- The table is provided with T-slots on its top surface, so that the workpiece may be clamped securely on the table.

- Two vertical columns, one on each side of the bed and table are located as shown in the figure.

- A cross rail can slide up and down on the two vertical columns.

- Usually, one or two tool posts (tool heads) are mounted on the cross rail and one side tool head is mounted on each column.

- Vertical tool heads can move laterally on the cross rail while side tool heads can move up and down on the vertical columns.

- There is an arrangement for the advancement or retraction of tools in the tool heads. A number of speeds and feeds are available for the tool heads.

💡 Even on a planer, the tools will cut material only in the forward stroke of the table, its return stroke is idle. To save idle time, the return stroke takes place at a higher speed. This is achieved by a variable speed reversible motor drive and a system of limit switches fitted on the bed of the machine, which gets actuated when the table reaches the end of its forward and reverse strokes. The length of the stroke can be adjusted to suit the length of the workpiece by changing the position of the limit switches.

Planning Machine Cutting Tools

The planner tools are made of high-speed steel, although tipped carbide tools are also used occasionally. These tools are, in general, similar to shaper tools, but are more robust and stronger. Specially shaped tools are used on planers for operations like T-slot cutting and dovetail slide cutting. In both shapers and planers, the tool or table starts from rest, picks up speed and then again slows down to zero speed during the forward or cutting stroke. It is customary to calculate cutting speed on the basis of average speed during the forward stroke. Feed and depth of cut are both expressed in mm. In the case of feed, it is the lateral distance moved by the tool (on the cross-rail) per cutting stroke.

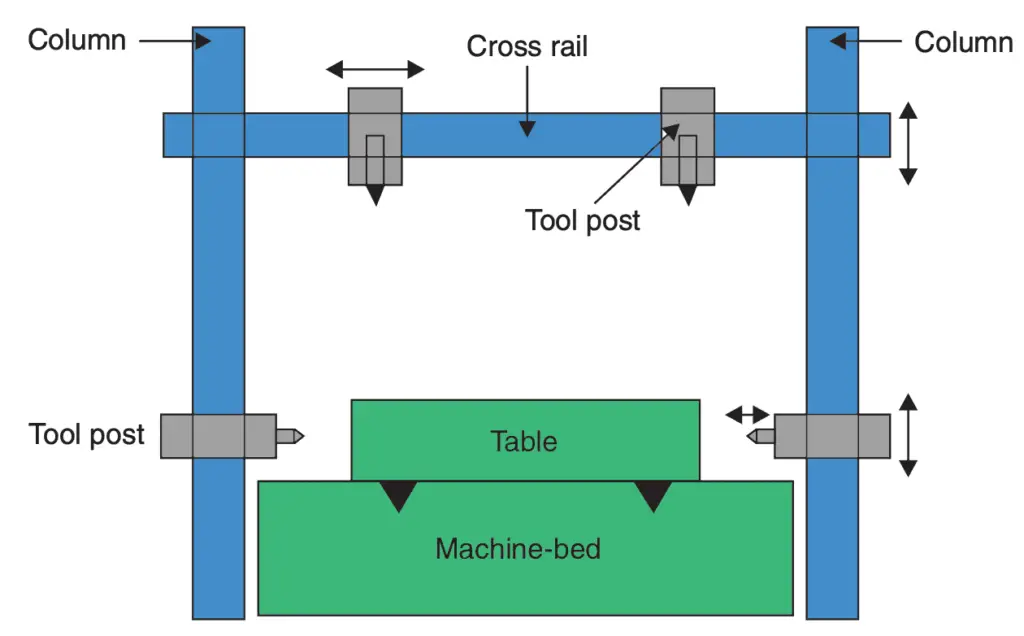

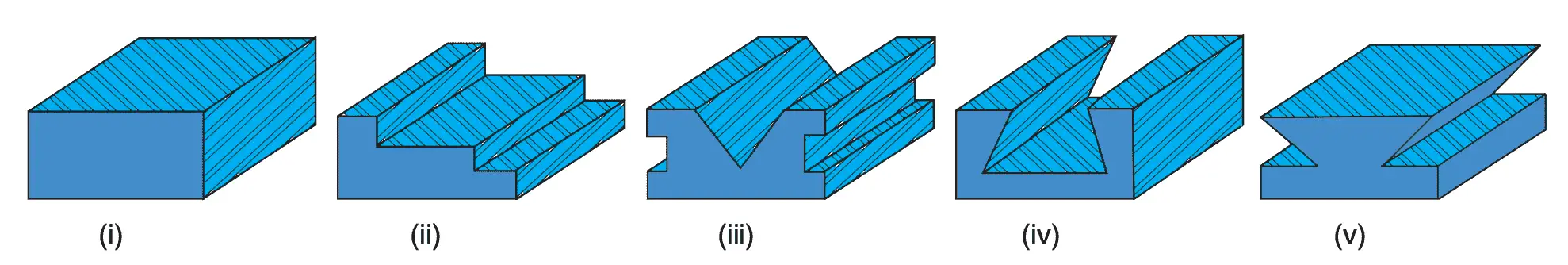

Let us see some examples of the diverse type of machining operations performed on a planer can be had by referring to the following figure. The surfaces shown shaded have been machined on the planer.

This is all about the Shapers and Planers.

Conclusion

The Shapers and Planers machine is capable of machining a horizontal, vertical or inclined flat surface. We have explained the different operations that can be performed with the shaper and also the operation and working principle of the quick return mechanism which is the main heart of this shaper and planar machines. let us know what you think about this article in the comment section below.

Leave a Reply