In the power transmission domain, the clutch has a significant role for transmitting the power between driver and driven which must be started and stopped frequently. A Clutch is used in this application to do the job. Let’s discuss more details on the Friction Clutch.

Friction Clutch

A friction clutch is a device is used in the automobiles to connect the engine to the driven shaft. The friction force is used to start the driven shaft from rest and gradually brings it up to the proper speed without excessive slipping of the friction surfaces.

During the clutch engaging, dis-engaging condition, certain care should be taken for the friction clutches.

- Proper alignment of the bearing should be maintained.

- Contact surfaces should develop a required frictional force to pick and hold the load with reasonably low pressure between the contact surfaces.

- The clutch plate should be able to dissipate the heat more efficiently and The tendency of catching the heat should less.

- The clutch surfaces should be stiff enough to distribute the pressure uniformly.

Friction Clutch Types

- Disc or plate clutches (single disc or multiple disc clutch)

- Cone clutches

- Centrifugal clutches

The disc and the cone clutches are based on the same theory as the pivot and collar bearings.

Friction Clutch Construction

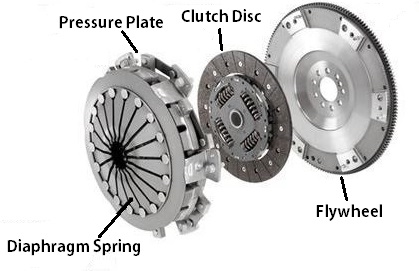

A friction clutch will consist of the following main components

- Flywheel

- Pressure plate

- Clutch Plate

Flywheel

This is the primary part which is going to connect with the engine output. The clutch plate will be installed next to it. As the pressure plate applies pressure on the clutch plate, the clutch plate will engage with the flywheel. This flywheel can be made to match some standard SAE(Society of Automotive Engineering) sizes, or also with Non-SAE sizes also. These Flywheels are typically made of steel.

Clutch Plate

A clutch plate or disc is the main component in the Friction clutches. This disc or plate is a metallic plate with frictional surfaces on both sides of the disc. This frictional surfaces should be made up of high friction coefficient material, Which will ensure the transmitting the torque without any slipping.

Pressure plate

A pressure plate used to apply the pressure on to the clutch plates to maintain the proper contact between the clutch surfaces flywheel surfaces by means of springs which are attached to it. In automobiles, this pressure plate will be given control to the lever to engage and disengage frequently.

Friction Clutch Working

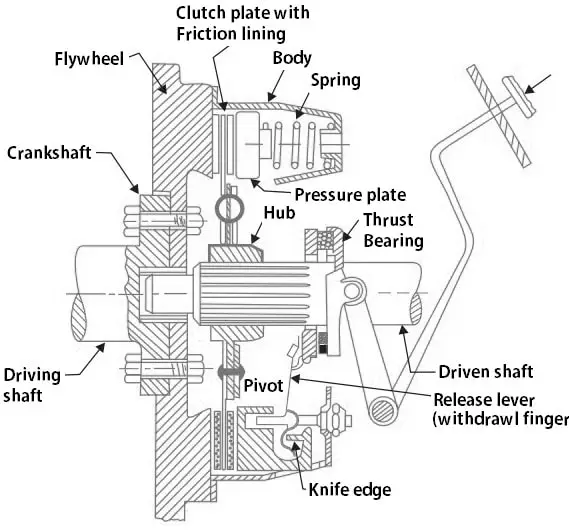

As you can see the above schematic representation of the single-disc clutch. As we mentioned above, the flywheel will connect with the driveshaft and the clutch plate will be held on to the flywheel by means of pressure applied by the pressure plate. This pressure plate will be having a helical spring or a diaphragm spring.

This pressure plate always put on the pressure on the clutch plate. which means the clutch will be always engaged to the flywheel. A lever mechanism will be provided to lift the pressure on the clutch plate to disengage from the flywheel whenever required.

Friction Clutch Applications

The Automobile industry is one of the major application for friction clutches widely.

And also where we use the diesel engines, there is a possibility of usage of the clutch. But there are different clutches also available as well. Such as turbo clutch. So this can be a friction clutch or any other kind of clutch based on customer preference.

Conclusion

We have discussed what is the Clutch, different types of a friction clutch, the clutch working principle, construction, and Clutch applications. If you have any further thoughts on this topic, let us know in the comment section below.

Leave a Reply