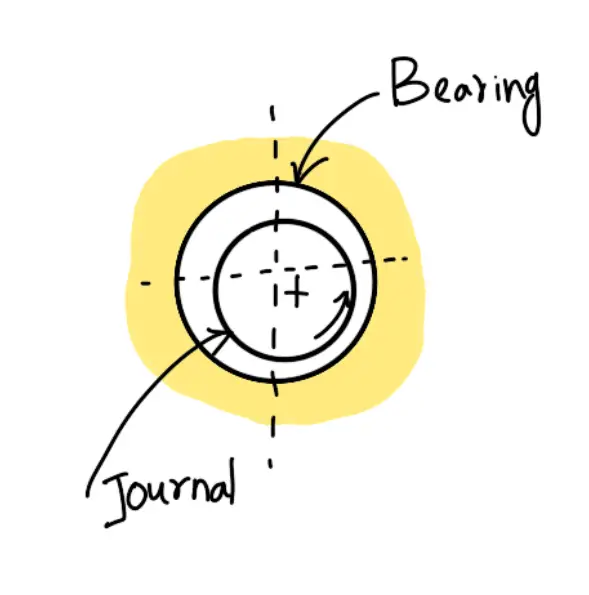

A bearing is a machine element that supports another moving machine element known as a journal. It enables a relative motion between the contact surfaces of the members while carrying the load. While doing so a certain amount of power is wasted in overcoming frictional resistance due to the relative motion between the contact surfaces. We need to study the types of Bearings, design, and materials used for bearings briefly. In this article, let us discuss the Classification of Bearings.

A little consideration will show that a certain amount of power is wasted in overcoming frictional resistance due to the relative motion between the contact surfaces. If the rubbing surfaces are in direct contact, there will be rapid wear. To reduce frictional resistance and wear and in some cases to carry away the heat generated, a layer of fluid known as lubricant may be provided. The lubricant used to separate the journal and bearing is usually a mineral oil refined from petroleum, but vegetable oils, silicon oils, greases, etc., may be used.

Classification of Bearings

Though the bearings may be classified in many ways, the following are the most important across the Mechanical industry.

1. Depending upon the direction of the load to be Supported

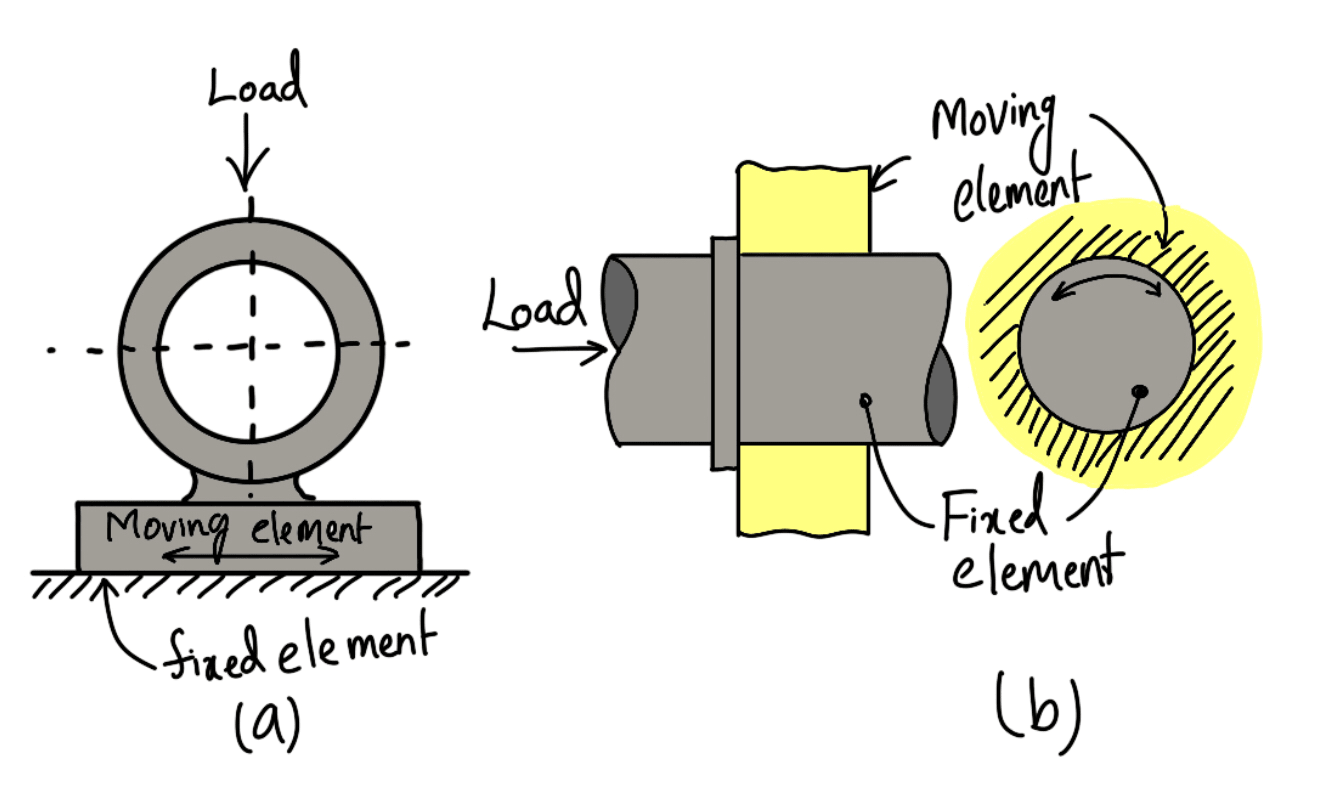

(a) Radial bearings: In radial bearings, the load acts perpendicular to the direction of motion of the moving element as shown in the following figures (a) and (b).

(b) Thrust bearings: In thrust bearings, the load acts along the axis of rotation as shown in the following figure.

2. Depending upon the nature of contact

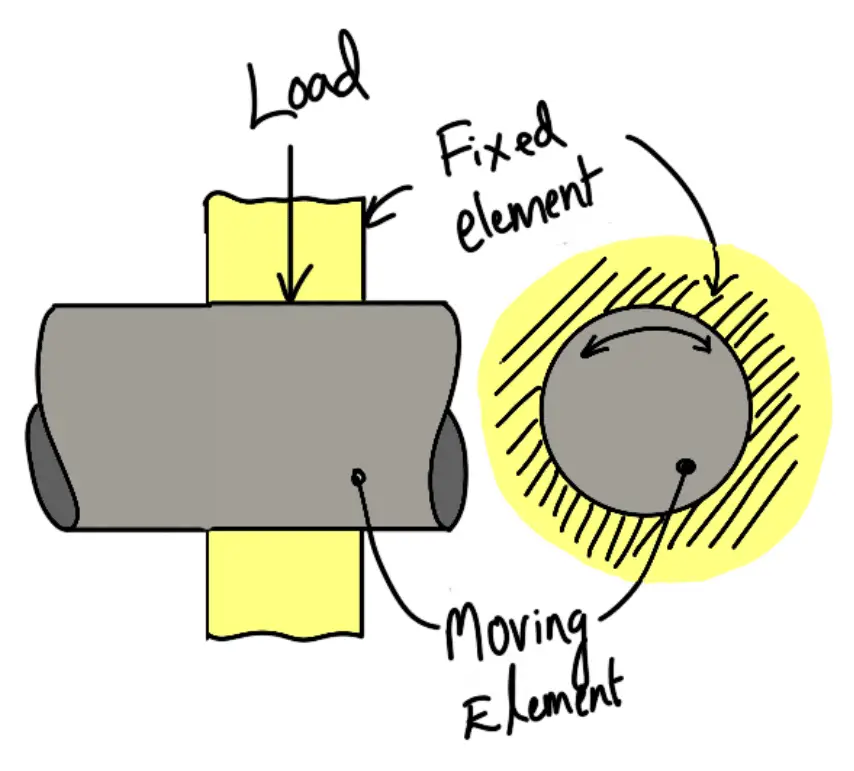

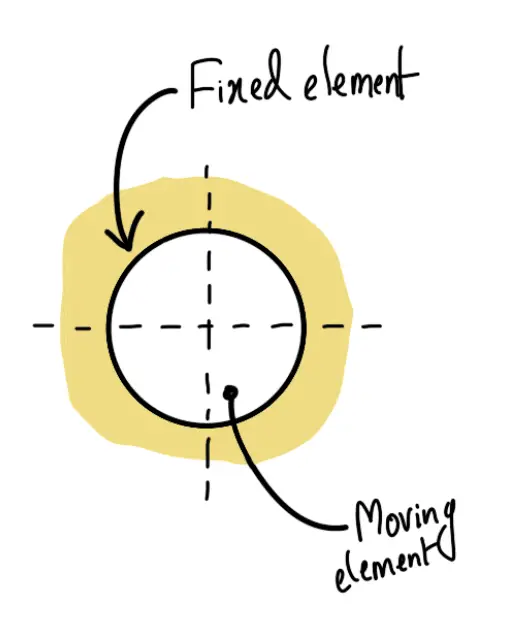

(a) Sliding contact bearings: In sliding contact bearings, as shown in the following figure, the sliding takes place along the surfaces of contact between the moving element and the fixed element. The sliding contact bearings are also known as plain bearings.

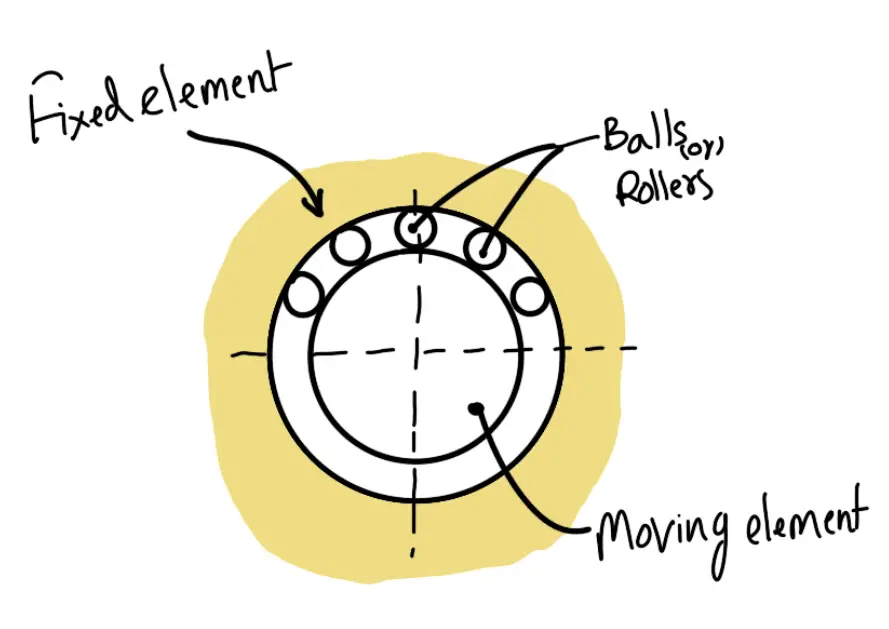

(b) Rolling contact bearings: In rolling contact bearings, as shown in the following figure, the steel balls or rollers, are interposed between the moving and fixed elements. The balls offer rolling friction at two points for each ball or roller.

These are the primary classifications. Let us now give a brief details about some of these types of bearings.

Sliding Contact Bearings

The sliding contact bearings in which the sliding action is guided in a straight line and carrying radial loads, as shown in the following figure, may be called slipper or guide bearings. Such types of bearings are usually found in cross-head of steam engines.

The sliding contact bearings in which the sliding action is along the circumference of a circle or an arc of a circle and carrying radial loads are known as journal or sleeve bearings. When the angle of contact of the bearing with the journal is 360° as shown in the above figure, then the bearing is called a full journal bearing. This type of bearing is commonly used in industrial machinery to accommodate bearing loads in any radial direction.

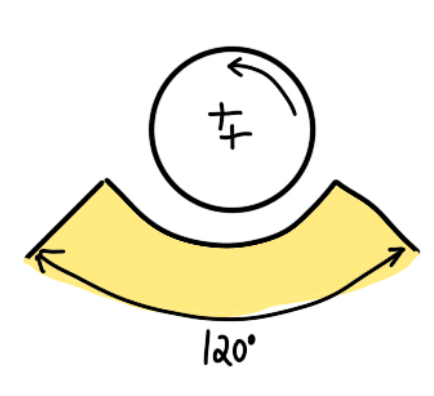

When the angle of contact of the bearing with the journal is 120°, as shown in the following figure, then the bearing is said to be a partial journal bearing. This type of bearing has less friction than a full journal bearing, but it can be used only where the load is always in one direction. The most common application of the partial journal bearings is found in railroad car axles. The full and partial journal bearings may be called as clearance bearings because the diameter of the journal is less than that of the bearing.

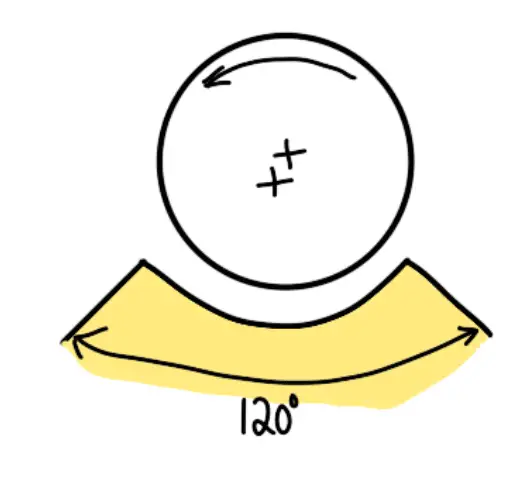

When a partial journal bearing has no clearance i.e. the diameters of the journal and bearing are equal, then the bearing is called a fitted bearing, as shown in the following figure.

The sliding contact bearings, according to the thickness of the layer of the lubricant between the bearing and the journal, may also be classified as follows:

- Thick film bearings: The thick film bearings are those in which the working surfaces are completely separated from each other by the lubricant. Such types of bearings are also called hydrodynamic lubricated bearings.

- Thin film bearings: Thin film bearings are those in which, although lubricant is present, the working surfaces partially contact each other at least part of the time. Such types of bearings are also called boundary-lubricated bearings.

- Zero film bearing: The zero film bearings are those that operate without any lubricant present.

- Hydrostatic or externally pressurized lubricated bearings: Hydrostatic bearings are those that can support steady loads without any relative motion between the journal and the bearing. This is achieved by forcing externally pressurized lubricant between the members.

Hydrodynamic Lubricated Bearings

We have already discussed that in hydrodynamic lubricated bearings, there is a thick film of lubricant between the journal and the bearing. A little consideration will show that when the bearing is supplied with sufficient lubricant, pressure is built up in the clearance space when the journal is rotating about an axis that is eccentric with the bearing axis. The load can be supported by this fluid pressure without any actual contact between the journal and the bearing. The load-carrying ability of a hydrodynamic bearing arises simply because a viscous fluid resists being pushed around. Under the proper conditions, this resistance to motion will develop a pressure distribution in the lubricant film that can support a useful load.

The load supporting pressure in hydrodynamic bearings arises from either

- The flow of a viscous fluid in a converging channel is known as wedge film lubrication.

- The resistance of a viscous fluid to being squeezed out from between approaching surfaces is known as squeeze film lubrication.

Wedge Film Journal Bearings

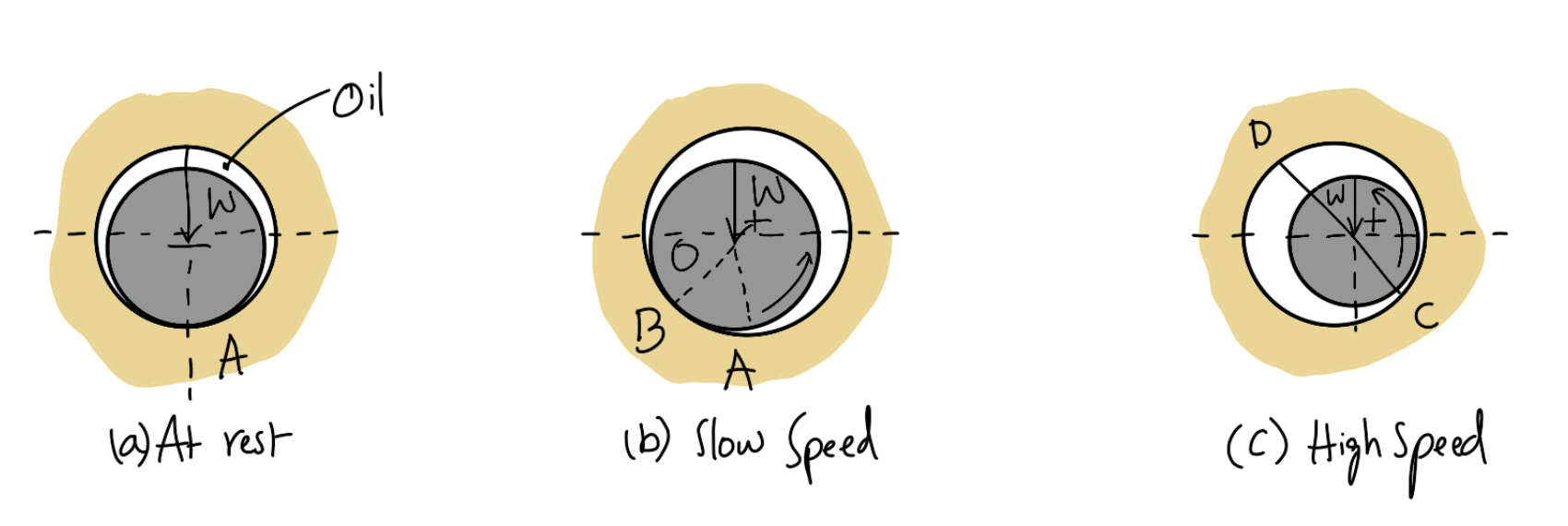

The load-carrying ability of a wedge-film journal bearing results when the journal and/or the bearing rotates relative to the load. The most common case is that of a steady load, a fixed (non-rotating) bearing, and a rotating journal. Figure (a) shows a journal at rest with metal-to-metal contact at A on the line of action of the supported load. When the journal rotates slowly in the anticlockwise direction, as shown in figure (b), the point of contact will move to B, so that the angle AOB is the angle of sliding friction of the surfaces in contact at B. In the absence of a lubricant, there will be dry metal-to-metal friction. If a lubricant is present in the clearance space of the bearing and journal, then a thin absorbed film of the lubricant may partly separate the surface, but a continuous fluid film completely separating the surfaces will not exist because of slow speed.

When the speed of the journal is increased, a continuous fluid film is established as in the above figure (c). The center of the journal has moved so that the minimum film thickness is at C. It may be noted that from D to C in the direction of motion, the film is continually narrowing and hence is a converging film. The curved converging film may be considered as a wedge-shaped film of a slipper bearing wrapped around the journal.

Squeeze Film Journal Bearing

We have seen in the previous article that in a wedge film journal bearing, the bearing carries a steady load and the journal rotates relative to the bearing. But in certain cases, the bearings oscillate or rotate so slowly that the wedge film cannot provide a satisfactory film thickness. If the load is uniform or varying in magnitude while acting in a constant direction, this becomes a thin film or possibly a zero film problem. But if the load reverses its direction, the squeeze film may develop sufficient capacity to carry the dynamic loads without contact between the journal and the bearing. Such bearings are known as squeeze film journal bearings.

Solid Journal Bearing

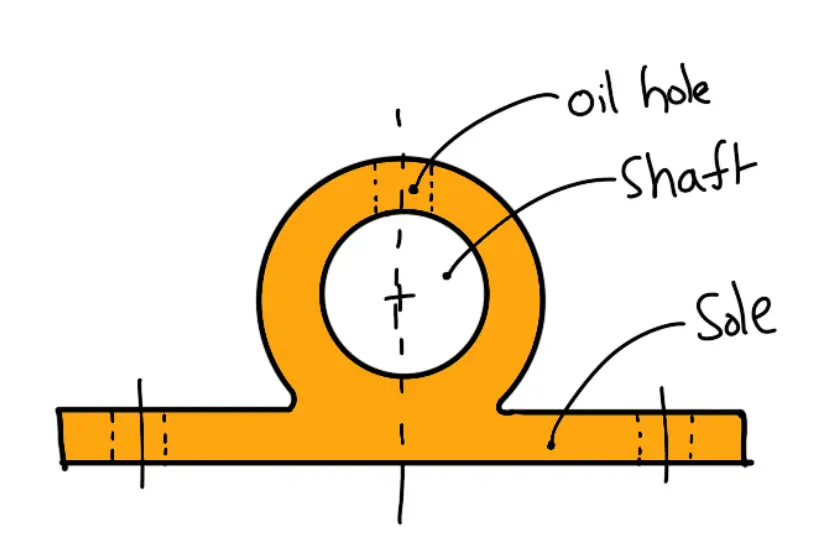

A solid bearing, as shown in the following figure, is the simplest form of journal bearing. It is simply a block of cast iron with a hole for a shaft providing a running fit.

The lower portion of the block is extended to form a base plate or sole with two holes to receive bolts for fastening it to the frame. An oil hole is drilled at the top for lubrication. The main disadvantages of this bearing are

- There is no provision for adjustment in case of wear

- The shaft must be passed into the bearing axially, i.e. endwise.

Since there is no provision for wear adjustment, therefore this type of bearing is used when the shaft speed is not very high and the shaft carries light loads only.

Bushed Bearing

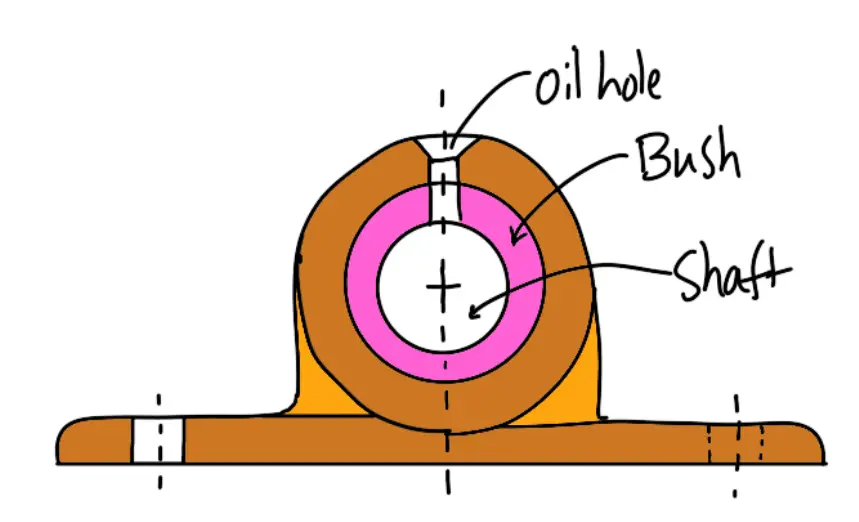

A bushed bearing, as shown in the following figure, is an improved solid bearing in which a bush of brass or gunmetal is provided.

The outside of the bush is a driving fit in the hole of the casting whereas the inside is a running fit for the shaft. When the bush gets worn out, it can be easily replaced. In small bearings, the frictional force itself holds the bush in position, but for shafts transmitting high power, grub screws are used for the prevention of rotation and sliding of the bush.

Split Bearing or Plummer Block

A split bearing is used for shafts running at high speeds and carrying heavy loads. A split-bearing, as shown in the following figure, consists of a cast iron base (also called block or pedestal), gunmetal or phosphor bronze brasses, bushes or steps made in two halves, and a cast iron cap.

The two halves of the brasses are held together by a cap or cover using mild steel bolts and nuts. Sometimes thin shims are introduced between the cap and the base to provide an adjustment for wear. When the bottom wears out, one or two shims are removed and then the cap is tightened using bolts.

The brasses are provided with collars or flanges on either side to prevent axial movement.

Thrust Bearings

A thrust bearing is used to guide or support the shaft which is subjected to a load along the axis of the shaft. Such types of bearings are mainly used in turbines and propeller shafts. The thrust bearings are of the following two types :

a) Footstep or Pivot bearings

b) Collar Bearings

In a footstep or pivot bearing, the loaded shaft is vertical and the end of the shaft rests within the bearing.

In the case of collar bearing, the shaft continues through the bearing. The shaft may be vertical or horizontal with a single collar or many collars.

These are some of the important types of bearings that we need to be aware of from the mechanical engineering point of view. We have discussed these bearings in more detail with the design aspects in the respective articles. Follow the links and let us know what you think about these articles in the comment section below.

Leave a Reply