In the Design of any machine elements, it is necessary to follow the Geometric dimensioning and tolerancing for the Holes or shafts. The Least Material Condition(LMC) is the feature of the size where it can be called out for a hole or a shaft feature on the drawing.

Least Material Condition (LMC)

It refers to a feature of size. (The feature of size is nothing but the set of parallel surfaces associated with the size dimension.)

This is a condition where there exists a minimum amount of material within the given dimension tolerance zone for the part or the feature.

If the MMC callout is on the hole feature then the hole feature should have the largest size. if the MMC callout is on the shaft or pin feature then the shaft or pin feature should have the smallest size within the tolerance zone.

LMC is used where the wall thickness is important, like holes on gaskets and flanges and minimum machining is required.

LMC is fairly rare in GD&T. The reason to call out the LMC is close/interference between the two mating parts.

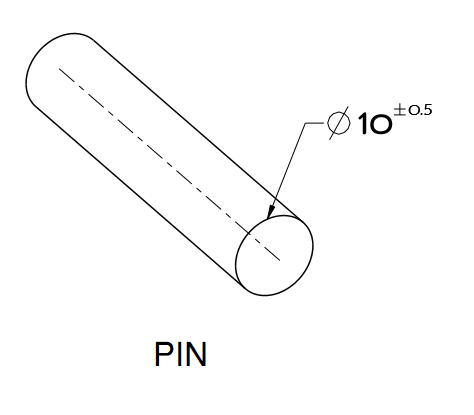

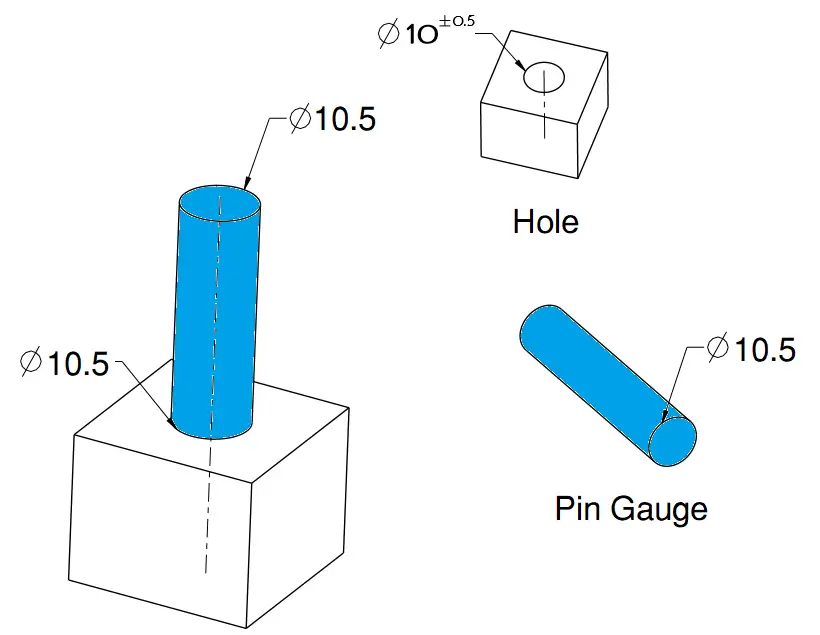

See the below LMC conditions for Pin and Hole

LMC condition for a pin with No-GO gauge

The pin will have the minimum diameter within the tolerance limit. (i.e Ø9.5)

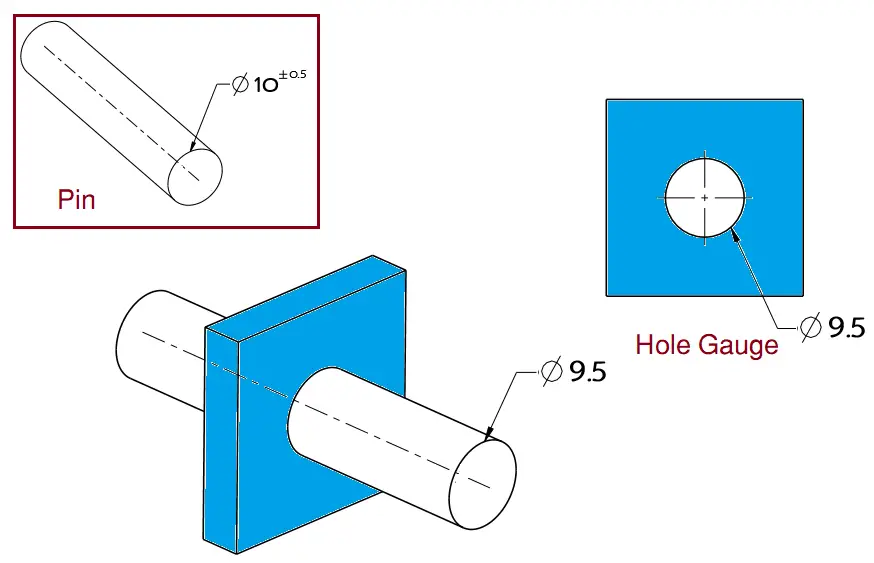

Gauging Least material condition for a pin

A pin always tight fit into a hole, when the pin is in the LMC condition. So that we need to design the Hole Gauge for the pin. so this hole gauge controls the Least material condition for the pin. this gauge is called No-GO GAUGE.

The Hole gauge is having the diameter same as the Pin maximum diameter(Ø).

The formula to find the Hole Gauge Diameter(Ø)= Minimum Diameter(Ø) of LMC Pin

The No-Go Gauge would be designed ~2µm smaller to make up for any error.

We can not use GD&T with the No-Go Gauge.

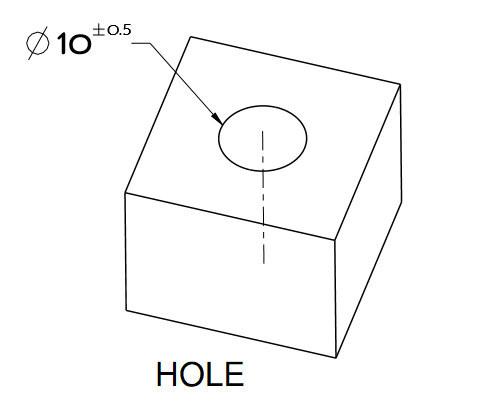

LMC condition for Hole with No-Go Gauge

The Hole will have the maximum diameter within the tolerance limit. (i.e Ø10.5)

Gauging Least material condition for Hole

a pin always tight/press fits into a hole when the hole is at LMC So that we will design the Pin Gauge for the HOLE. so this pin gauge controls the Least material condition for the hole.

The Pin gauge is having the diameter same as the Hole maximum diameter(Ø).

The formula to find the Pin Gauge Diameter(Ø)= Min Diameter(Ø) of LMC

The No-Go Gauge will be designed ~2µm larger to make up for any error.

Where can we apply Least Material Condition?

LMC is rarely used and will not combine with the GD&T tolerances, due to being unable to accurately gauge for size and geometry tolerances.

The feature of Size Callouts in GD&Ts

- Maximum material Condition

- Least Material Condition

- Regardless of the feature of size

Regardless of the feature of size

When there is no call out to Maximum Material Condition or Least Material Condition, the part, by default, is measured regardless of feature size (RFS).

Wow! When a hole is at LMC, a pin always tightens/presses into it. As a result, they’ll create a Pin Gauge for the HOLE. As a result, the Least Material Condition for the hole is controlled by this pin gauge. Thank you so much for this helpful article.