Have you ever seen the Failure of Riveted joints?

That’s right. that is one of the ways it fails. There is shear in the Rivets as per the above failure picture. The following image is a sample of the Failure of a Riveted joint due to the tearing of the plate.

So, there are different possible ways that a Riveted Joint can fail. Following are the 4 different ways that a Riveted Joint can fail.

- Tearing of the plate at an edge

- Tearing of the plate across a row of rivets

- Shearing of the rivets

- Crushing of the plate or rivets

Let us discuss those possible ways of Failure in Riveted Joints.

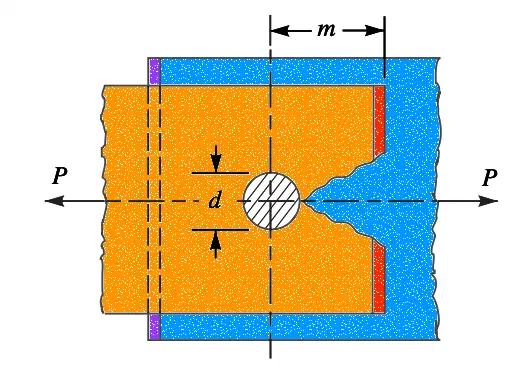

1. Tearing of the plate at an edge

As shown in the above diagram, the tearing may happen at the nearest edge of the plate. to avoid such tearing for the riveted joints, we need to maintain the margin m = 1.5d, where d is the diameter of the hole.

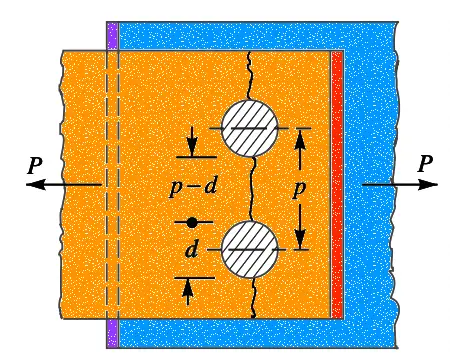

2. Tearing of the plate across a row of Rivets

The Riveted Joint maybe fail due to the tensile stress in the plates. The Failure happens in the plate across the row of rivets as shown in the above diagram.

Let us define how we can prevent this Failure in Riveted Joints.

Let us consider one pitch length of the plate. (Every rivet causes the failure along this pitch length on the plate).

Let us assume the Pt is the tearing resistance or tearing strength to resist the tearing in the plate.

p = Pitch of the rivets

d = Diameter of the rivet hole

t = Thickness of the plate

σt = Permissible tensile stress for the plate material

From the above schematic diagram, the tearing area can be obtained is At = (p–d)t

∴ Tearing resistance or pull required to tear off the plate per pitch length is,

Pt = At.σt

Pt = (p – d)t.σt

From this expression, we can say that when the tearing resistance (Pt) is greater than the applied load (P) per pitch length, then this type of failure will not occur.

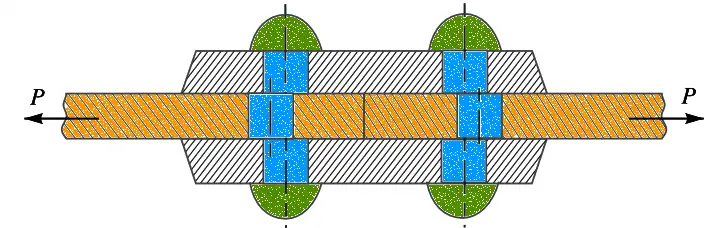

3. Shearing of the Rivets

As shown in the above animation, the plates which are connected by the rivets exert the shear stress on the Rivet body/shank. If this shear stress is unable to resist by the rivet body, then they will be sheared off.

In the above animation, the rivet is being sheared can be said as single shear when they are in Lap joint. If they are in but joint they will experience the double shear. this phenomenon is shown below with the Butt joint.

Let us determine how we can prevent such shearing Failure in Riveted Joints.

Let us assume the Ps is the shearing resistance or shearing strength to resist the shearing in the rivet.

d = Diameter of the rivet hole

τ = Safe permissible shear stress for the rivet material

n = Number of rivets per pitch length.

From the above diagram for a single shear in lap joint, the shearing area give by

As = (π/4)d2

If there is a double shear in the butt joint then the shearing area give by

As = 2 × (π/4)d2 (As = 1.875 × (π/4)d2 …… as per Indian Boiler Regulations)

∴ Shearing resistance or pull required to shear off the rivet per pitch length,

Ps = n × As × τ

Ps = n × (π/4)d2 × τ ………. for single shear in Lap Joint

Ps = n × 2×(π/4)d2 × τ ……… For double shear in the Butt joint

Ps = n × 1.875×(π/4)d2 × τ ……… For double shear in Butt joint as per Indian Boiler Regulation

When the shearing resistance (Ps) is greater than the applied load (P) per pitch length, then this type of failure will occur.

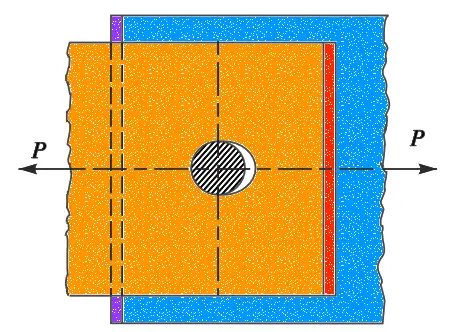

4. Crushing of the Plate or Rivets

The fourth possibility of the Riveted joint failure happens when the rivet is crushed instead of sheared off and the circular hole in plates turned into an oval shape instead of the plates tearing. Due to this, the Riveted Joint becomes loose.

This kind of failure in Riveted joint in such a manner is referred to as bearing failure. The area which resists this action is the projected area of the hole or rivet on the diametral plane.

Let us determine how we can prevent such crushing of the rivet in Riveted Joints.

Let us assume the Pc is the Crushing resistance or Crushing strength to resist the crushing in the rivet.

d = Diameter of the rivet hole

t = Thickness of the plate

σc = Safe permissible crushing stress for the rivet or plate material

n = Number of rivets per pitch length under crushing

From the above diagram, the crushing area is

Ac = d.t

The total crushing area will be = n.d.t

∴ Crushing resistance or pull required to crush the rivet per pitch length is given by

Pc = n.d.t.σc

When the crushing resistance (Pc) is greater than the applied load (P) per pitch length, then this type of failure will occur.

How to detemine a Riveted Joint is Safe?

We have discussed different failures in Riveted Joints. Also, we determined the resisting force equations Pt, Ps and Pc for each of the Above failures respectively.

Now we have to make sure that above all three resisting pulls should always be greater than the applied loads. That is the way we can make sure the Riveted Joint is safe.

This maximum force, which it can transmit, without causing it to failure of the Riveted joint is called the Strength of the Riveted Joint.

But how effective are these riveted Joints when compared to the other Joining methods?

That is why we need to calculate the efficiency of the Riveted joint.

But how?

Efficiency of the Riveted Joint

The efficiency of a riveted joint is defined as the ratio of the strength of riveted joint to the strength of the un-riveted or solid plate.

We have already discussed that strength of the riveted joint = Least of Pt, Ps, and Pc

Strength of the un-riveted or solid plate per pitch length, P = p × t × σt

p = Pitch of the rivets,

t = Thickness of the plate, and

σt = Permissible tensile stress of the plate material.

∴ The efficiency of the riveted joint, η = (Least of Pt, Ps and Pc) / (p × t × σt)

Conclusion

We have discussed the failure of riveted joints in 4 possible ways and determined how we can prevent such failures. And determined how a Riveted joint is safe. Discussed the efficiency of the Riveted Joint. let us know what do you think about this in the comment section below.

Leave a Reply